Mazuva ano zvinhu zvepurasitiki 'kushandisa zvizere hupenyu hwedu, chero mumba kana maindasitiri.Asi iwe unonyatsoziva kugadzira achikamu chepurasitiki?Ramba uchiverenga, chinyorwa ichi chichakuudza.

Chii chinonzi injection mold

Jekiseni molding rinowanzotsanangurwa se thermoplastic polymer rinopisa pamusoro pekunyunguduka kwayo, zvichikonzera kushandurwa kwepolymer yakasimba kuita mvura yakanyunguduka ine viscosity yakaderera zvine musoro.Uku kunyunguduka kunomanikidzwa nemichina, ndiko kuti, kubaiwa, muforoma muchimiro chechinhu chekupedzisira chinodiwa.Pakugadzirwa kwemaindasitiri, kuumba jekiseni ndeimwe yeakanyanya kukosha maitiro ekuwanda-kugadzirwa kwezvinhu kubva ku thermoplastics.Vashandi vanowanzodira mapurasitiki akaoma emidziyo (senge: ABDS, PP, TPU, PA66) mudhiramu remuchina wekuumba jekiseni.Zvino maererano nezvinodiwa zvakasiyana zvechigadzirwa, tembiricha dzakasiyana uye kumhanya kwejekiseni zvinogadzirwa.Wobva waisa tembiricha dzakasiyana uye kumhanya kwejekiseni zvinoenderana nezvinodiwa zvakasiyana zvechigadzirwa.Mushure mekutonhora kwekupedzisira kugadzira chigadzirwa, chinoburitswa nepini ejector.

Sei uchida tsika jekiseni mold

1.Product kuvanzika uye kuchengeteka

Munguva yekuburitswa kwechigadzirwa, zvinowanzoitika kuti zvigadzirwa zvakagadzirirwa kwenguva yakareba zvakapirwa zvisati zvaburitswa.Izvi zvinowanzoitika nekuda kwekuti vatengi vanoshandisa akasiyana akagadzirira-akagadzirwa mold kuti aasanganise pamwe chete panguva yekugadzira uye jekiseni molding process, uye havana yavo seti yekuumbwa.Paunenge uchigadzirisa seti yezvigadziro zvezvigadzirwa zvako, dambudziko iri harichaitike, nekuti isu tichachengeta molds pamusimboti wekuti iwe chete ndiwe unogona kuashandisa, uye gara uchigadzirisa pazviri kuti ubatsirwe.Ishandise chero nguva gare gare.

2.Complexity

Paunosarudza kugadzirisa seti ye molds, zvigadzirwa zvako hazvichatapukidzwa nechimiro uye mold.Nekuda kwehukuru hwerusununguko mukugadzirisa, unogona kugadzira zvimiro zvechigadzirwa zvakaomarara zvinoenderana nezvaunoda pachinzvimbo chekuzvibatanidza pamwechete kubva kune akawanda mold.Izvi zvichavandudza zvikuru kuvimbika uye kuvimbika kwechigadzirwa.Iine huwandu hwazvino hwemashandisirwo emajekiseni mold uye 3D kudhirowa, zvigadzirwa zvaunogadzira zvinogona kubva kumba kuenda kune zvigadzirwa zvemaindasitiri.

3.Mutengo wepasi

Kubva pakuona kwekugadzira, kugadzirisa mold kungada mutengo wakakwira pane kushandisa yakagadzirira-yakagadzirwa mold.Nekudaro, kubva padanho rekugadzira, kuumba jekiseni inzira yekugadzira yakawanda uye kushandiswa kwenguva refu kweakagadzirira-akagadzirwa mold yekugadzira splicing.Mitemo inotevera yakakwira zvakanyanya, saka kana ukasarudza yakagadziridzwa mold, hauzodi kubhadhara chero chinhu kune mold.

Nzira yekugadzira jekiseni mold

Gadzira Mold muCAD

Dhizaini yekuumbwa ndeimwe yematanho akakosha mukuita.Iri ndiro danho raunofanirwa kusarudza kuti chikamu chichaita sei, kuti chichagadzirwa sei uye kuti chichava chii.Jekiseni kuumba inzira yakaoma, uye mold chikamu chikuru cheiyo.Iyo mold inoda kukwanisa kumira kudzvinyirira kwakanyanya uye kupisa kwekuita jekiseni, pamwe nekudzokorora kushandiswa.Ndicho chikonzero nei zvakakosha kuwana dhizaini ye mold chaiyo kekutanga.CAD software inogona kukubatsira iwe kugadzira yakakwana 3D modhi yechikamu chako chaunogona kushandisa kugadzira mold.

3D Dhinda Mold

Danho rekupedzisira ndere kudhinda mold uchishandisa 3D printer.Izvi zvinogadzira yekupedzisira, chaiyo-saizi mold.Kana iwe usina chokwadi chekuita nezve izvi, kune akawanda online tutorials ekukubatsira kunze.Iwe unogona zvakare kuwana 3D kudhinda masevhisi anozoita basa racho kwauri.Kudhinda mold inhanho yakakosha, sezvo ichaita kuti chigadzirwa chakapedzwa chive chemhando yepamusoro.

Kana iwe uchida kuziva zvakawanda nezvekugadzira mold, unogona kuverengaMold Dhizaini uye Kugadzira kwePlastiki Zvikamu

Dambudziko rakajairika mukugadzira mold process

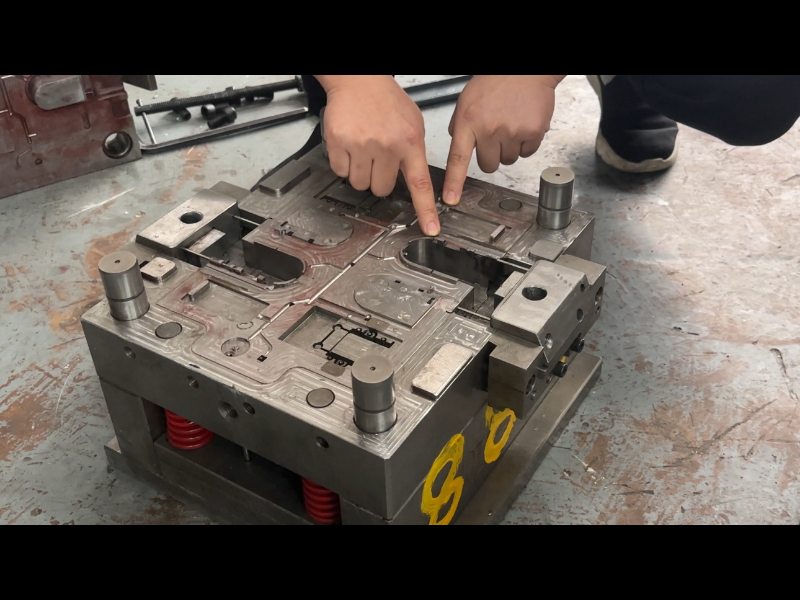

1.slider

Kana iyo inotsvedza ichisanganiswa ne splicing, haigone kukwana zvakakwana mold.Kana mold yakavhurwa uye yakavharwa, zviri nyore kuita kuti iyo yakarerekera kumusoro iputse.

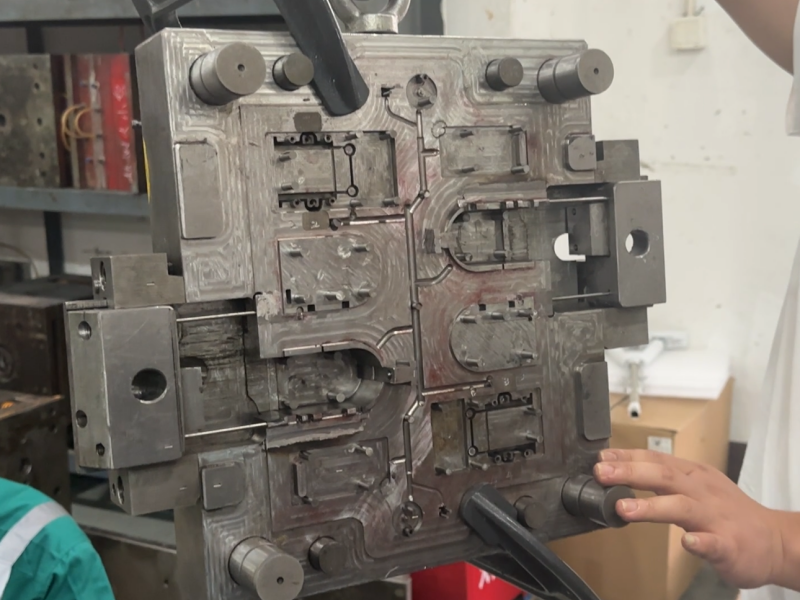

2.mugero wemvura

Iko hakuna nzira yekuyerera kwemvura yakarongwa paunenge uchigadzira mold, iyo inotarisana nematambudziko nekutonhora kwechigadzirwa.Uyezve, mushure mekushandiswa kwenguva refu kwe mold, tembiricha ye mold inokwira uye yakakwira, inozopedzisira yatungamira kune deformation yechigadzirwa kana kutsauka kwegomba chinzvimbo.

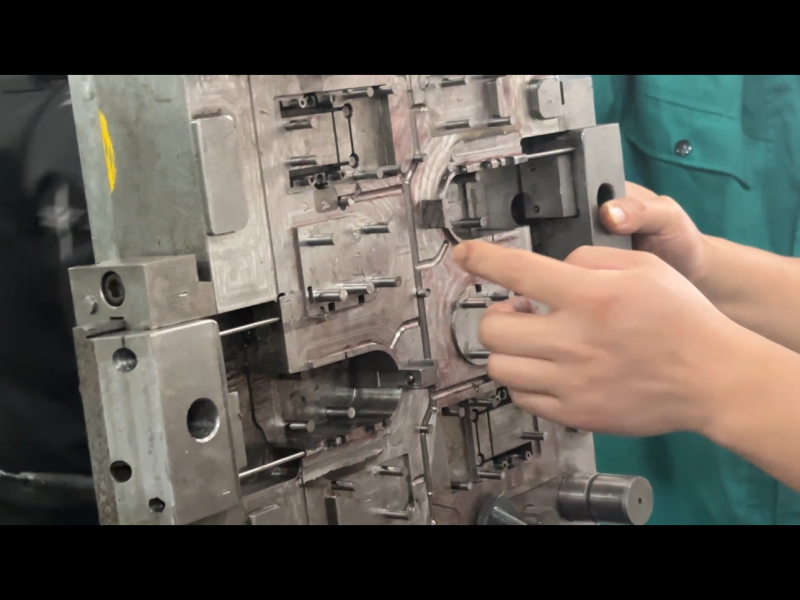

3.Mold kupfeka

Munguva yekugadzira dhizaini, nekuti hapana slots yakawedzerwa kubvumira mafuta kuti adzore mold, iyo friction coefficient pakati pesimbi zvidhinha panguva yekukuya yaive yakakura kwazvo, ichikonzera kukuvadza kune mold.

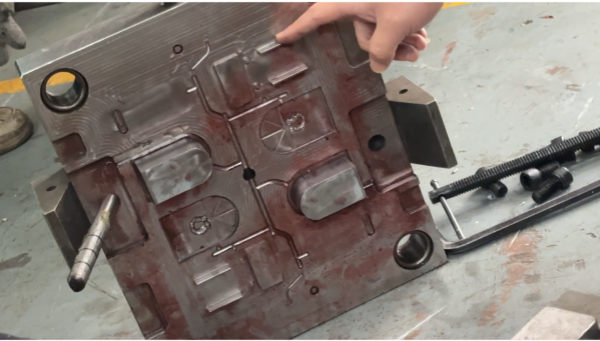

4.Product slot allocation haina musoro

Sezvo kuumbwa kwejekiseni kunosanganisira kubaya yakakwira-tembiricha yakanyungudutswa yemvura clinker mugoro re mold kuitira kutonhora kwekupedzisira kwechigadzirwa, iyo mold yezvigadzirwa zvakakura inofanirwa kunge iri padyo neglue inlet kudzivirira kutonhora kutonhora nekuda kwechinhambwe chakareba uye. kutadza kupinza zvinobudirira muforoma.Asi zviumbwa zvezvigadzirwa zviduku zvinoda plastiki shoma, saka grooves inowanzogadzirwa pamucheto wefodya.

5.Iyo simbi yekuramba iri muforoma yepakutanga

Simbi yekusara muforoma yekutanga haitsiviwa nekuisa.Kana kukanganisa kukaitika gare gare, chikamu chese chasara chemuviri wekutanga chinoda kuchekwa-chekwa-waya uye wozoiswa zvakare.

Kana iwe uchida kuziva rumwe ruzivo rwakabatana nezve jekiseni rekuumba maitiro kana kugadzira mold, ndapota sunungukabata timu yedu nyanzvi.

Nguva yekutumira: Kubvumbi-18-2024