Nhasi tinokurukura nezve electro-spark deposition's application mune simbi alloys, panguva imwe chete isu tichatarisa pane iyi tekinoroji maitiro ekugadzirisa mold mujekiseni rekugadzira majekiseni uye kukanda mold.

Chii chinonzi Electro-Spark Deposition?

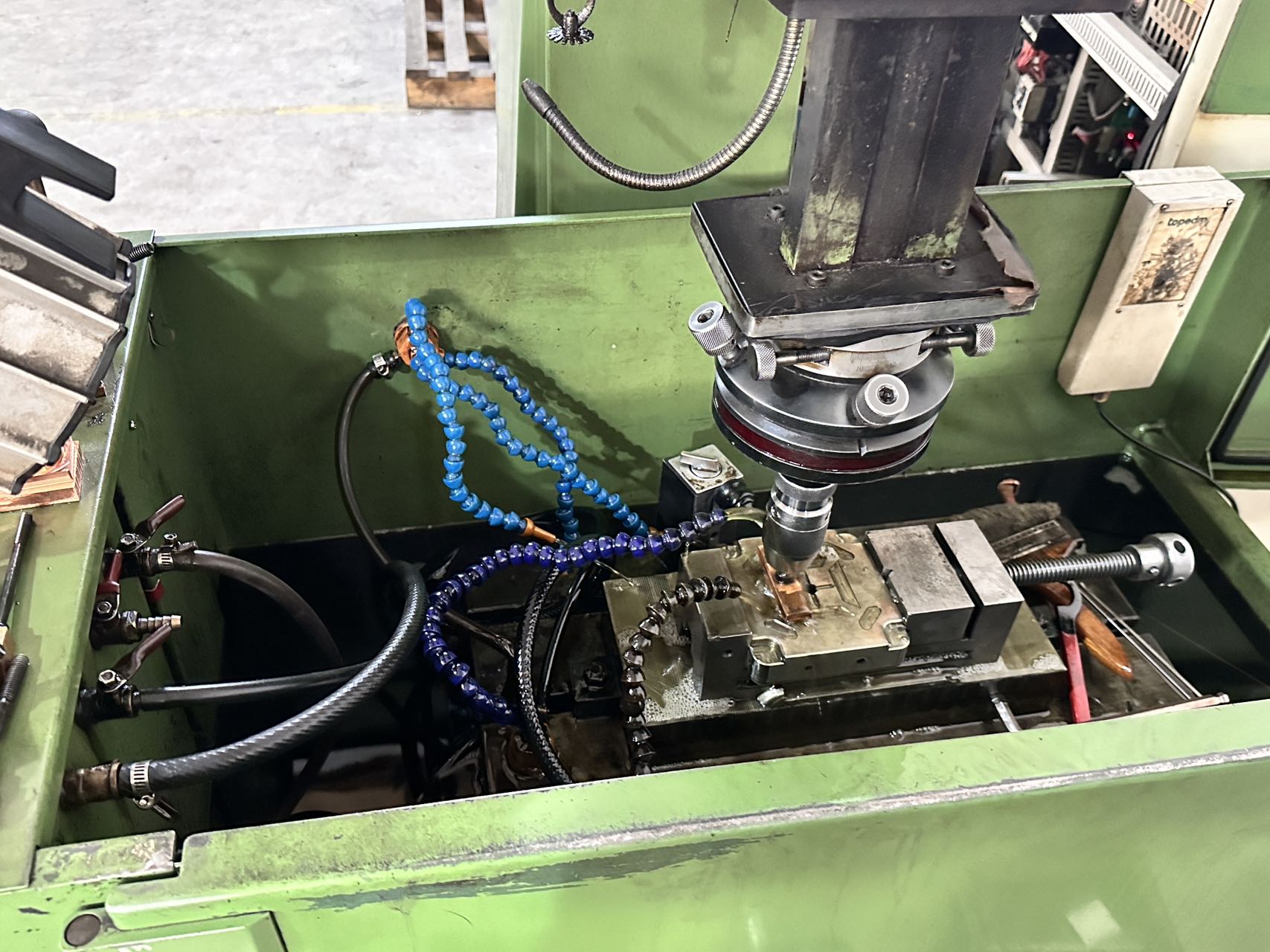

Electro-spark treatment, inozivikanwawo seElectro-discharge machining (EDM), inyanzvi yekugadzira iyo inosanganisira kushandiswa kwemagetsi anobuda kuumba uye kugadzirisa pamusoro pezvikamu zvesimbi.

Munguva yeElectro-spark kurapwa, kubuda kwemagetsi kunogadzirwa pakati pe electrode uye workpiece, inowanzogadzirwa nezvinhu zvinoitisa sesimbi kana alloys.Iyo nzira inotanga nekuisa iyo electrode, kazhinji iri muchimiro chediki, chakaumbwa chishandiso, padhuze neiyo workpiece.

Kana magetsi akaiswa pakati pe electrode uye workpiece, mutsara wekukurumidza kubuda kwemagetsi kunoitika.Izvi zvinobuda zvinogadzira kupisa kwakanyanya, kunyungudusa zvikamu zvidiki zvenzvimbo yebasa.Simbi yakanyungudutswa inobva yadzimwa nekukasira nedielectric fluid, zvichiita kuti iome uye igadzire ma crater madiki kana ma indentations.

ESD inoshandiswa kune simbi alloys

Kana iyo capacitor simba inoburitswa, iyo yakananga ikozvino inogadzira yakakwirira-tembiricha yeplasma arc pakati pe electrode tip uye metal alloy workpiece.Iyi tembiricha yepamusoro iri pakati pe8000 ne25000°C.Iyo plasma arc inoisa iyo anode uye inokurumidza kuendesa iyo yakanyungudutswa kune workpiece.

Iyi ionizing anode inoendeswa kune substrate kuburikidza nepfupi pulses.Iyo yepamusoro-tembiricha arc ine anode particles, kupisa kwemhepo (hot jet), uye plasma yakagadzirwa nekuparara kwemagasi uye maatomu anoshanda enitrogen, okisijeni, uye kabhoni.Kupisa kwakawanda kunotakurwa nejeti dzinopisa uye plasma.

Nemhaka yokuti pulses ipfupi, kupisa kwekushisa kuburikidza nejeti inopisa uye mamwe magasi ishoma, uye chete kupisa kunopisa kune substrate kuburikidza nenhamba shoma yeanode particles yakaiswa pane substrate.Nokudaro, mhepo idzi dzinoendesa zvishoma zvishoma zvekupisa kune substrate pasina kushandura microstructure ye substrate.Iyi nzira inonyanya kubatsira pane fusion welding process inowanzo shandiswa kugadzirisa alloys ane hurombo hunokanganisa kupisa kwenzvimbo zvivakwa (semuenzaniso, kushomeka kwakaderera, kuoma kwakanyanya, liquefaction kuparuka).

Pamusoro pezvo, maitiro aya anobatsira kugadzira chisungo chakasimba chesimbi pakati pe substrate uye yekupotera.Microalloying pakati pe electrode melt uye substrate inotanga kuumbwa kweplasma kuburikidza nekuparara kwemhepo, carbonates, carbides uye nitrides.

Zvakanakira

1.Kururamisa uye Kururamisa: Electro-spark treatment inobvumira kuumbwa kwakanyatsonaka uye kwakarurama kwezvinyorwa zvakaoma uye zvigadziriswe zvakaoma pamatare esimbi.Iwo anodzorwa emagetsi anoburitsa zvinhu nenzira inodzorwa, zvichigonesa kugadzirwa kwechokwadi maficha senge maburi madiki, slots, kana indentation ine yakakwirira dimensional kurongeka.

2.Kuchengetedzwa Kwekutendeseka Kwezvinhu: Chimwe chezvakakosha zvakanakira Electro-spark kurapwa ndiko kugona kwayo kuchengetedza kuoma uye kuvimbika kweiyo workpiece.Kusiyana nemaitiro echinyakare machining ayo anogona kuburitsa kupisa kwakanyanya uye kuunza shanduko isingadiwe mumidziyo, Electro-spark kurapwa inoderedza kupisa-inokanganiswa nzvimbo uye inochengetedza kuomarara kweiyo workpiece uye kurongeka kwechimiro.

3.Complex Geometries: Electro-spark treatment inogonesa machining ezvakaoma geometries zvingave zvinonetsa kana zvisingaite kuti zviwanikwe neyakajairwa machining nzira.Kugona kwayo kuumba yakaoma maficha inobvumira kugadzirwa kwe mold, inofa, kana zvimwe zvikamu zvine akasiyana contours uye yakaoma ruzivo, kuwedzera dhizaini mikana.

4.No Tool Wear: Kusiyana nemaitiro echinyakare machining anosanganisira kucheka kana abrasion, Electro-spark kurapwa haisanganisi kusangana kwakananga pakati pechishandiso uye workpiece.Nekuda kweizvozvo, kune kushoma kwezvishandiso kupfeka, zvichitungamira kune yakawedzerwa hupenyu hwematurusi uye kuderedzwa kwemitengo yekugadzirisa.

Summary

Ichi chinyorwa chinonyanya kuunza chirongwa che EDM mukugadzira mold, kwete kungounza kuyerera kwayo, asiwo kuunza zvakakosha zvakakosha zveiyi nzira.Kuburikidza nevhidhiyo iri pamusoro, ndinovimba iwe unogona kunzwisisa maitiro acho zvakajeka.Kana uine mimwe mibvunzo, ndapota inzwa wakasunungukataura nesu.

Nguva yekutumira: Jun-07-2024