Jekiseni kuumba pamusoro pekupedzisira senge SPI uye VDI classification masisitimu - Kupenya, semi-gloss, matte uye yakashongedzwa pamusoro pekupedzisira.

Zviri mukati zviri munyaya ino

- Chii chinonzi Injection molding surface inopera?

- Sei uchifanira kushandisa mapeji epamusoro mukuumba jekiseni?

- Injection mold tool surface finish specifications

- SPI Jekiseni kuumba pamusoro pekupedzisira

- VDI Jekiseni kuumba pamusoro pekupedzisira

- Nzira yekusarudza jekiseni rakakodzera rekuumba pamusoro pekupedzisira?

Chii chinonzi Injection molding surface inopera?

Injection molding surface finishyakakosha kune yakabudirira chikamu dhizaini uye inoshandiswa kune aesthetic uye inoshanda zvikonzero mupurasitiki jekiseni rekugadzira zvikamu zveinjiniya zvigadzirwa.Kupera kwepamusoro kunonatsiridza kutaridzika uye kunzwa kwechigadzirwa sezvo kukosha kunoonekwa uye kunaka kwechigadzirwa kunowedzera neakakodzera kumusoro.

Plastic Case (Mabviro:XR USA Mutengi)

Sei uchifanira kushandisa mapeji epamusoro mukuumba jekiseni?

Kuwedzera chikamu aesthetics

Vagadziri vechikamu vanogona kushandisa maumbirwo kune zvakasiyana siyana zveaesthetic zvinangwa.Iyo yakatsetseka kana matte yepasi mameseji inovandudza chitarisiko chayo uye inopa iyo yakakwenenzverwa chimiro.Inovhara zvakare zvikanganiso zvinogadzirwa nejekiseni moulding, senge mudziyo machining mamaki, sink mamaki, weld mitsetse, kuyerera mitsetse, uye mimvuri maki.Zvikamu zvine mhando yepamusoro yepamusoro zvinokwezva zvakanyanya kune vatengi kubva pakuona kwebhizinesi.

Kuvandudza chikamu chekushanda

Kunze kwekunakisa kufunga kunoenda pakusarudza jekiseni rekuumba pamusoro pekupedzisira, kune zvakare akakosha anoshanda kufunga.

Iyo dhizaini inogona kuda kubata kwakasimba kuti ishande zvakakwana.Textured epurasitiki kupera kunovandudza grip quality.Saka majekiseni ekuumba epamusoro marapirwo anowanzo shandiswa pazvinhu zvinotsvedza-resistant zvigadzirwa.Iyo yakaumbwa mold inogona zvakare kubatsira mukupukunyuka kwemagasi akavharirwa.

Iyo yakatsetseka SPI pamusoro pekupedzisira inogona kuita kuti pende ibvise.Zvisinei, nzvimbo yakaoma inogona kuvimbisa kuti pende inonamatira zviri nani kune chinhu chakaumbwa.A textured SPI pamusoro kurapwa inowedzerawo chikamu simba uye kuchengeteka.

Texture ine zvakawanda zvakanaka, kusanganisira:

- Plastic flow creases-Aya macrease anogona kubviswa nekuwedzera textured ukobvu uku uchiwedzera simba uye zvisiri-kutsvedza zvivakwa.

- Kubata kwakavandudzwa-Kuwedzera mameseji kune chikamu kunoita kuti kubata kuve nyore, kuwedzera kubatsira uye kuchengetedzeka mune chaiyo maapplication.

- Paint adhesion-Paint inonamatira zvakasimba kune chinhu chakagadzirwa panguva yekuumbwa kunotevera.

- Kuita undercuts-Kana iwe uine chikamu chisingarambe chichiuya kune inofamba hafu yekuumbwa, kutumira mameseji pane chero nzvimbo kunogona kupa pu inodiwa.ll.

Injection mold tool surface finish specifications

Nzira yakajairika yekutsanangura majekiseni ekuumba nzvimbo ndeye kushandisaPIA (kana SPI), VDIuyeMold-techmipimo.Injection mold toolmakers, vagadziri uye mainjiniya edhizaini pasi rese vanocherekedza aya matatu mazinga uye PIA zviyero zvakajairika uye zvinozivikanwa zvakanyanya se "SPI mamakisi".

Gloss finish – Giredhi A – Diamond kupera

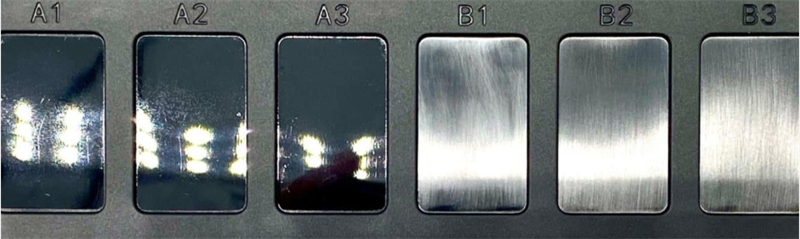

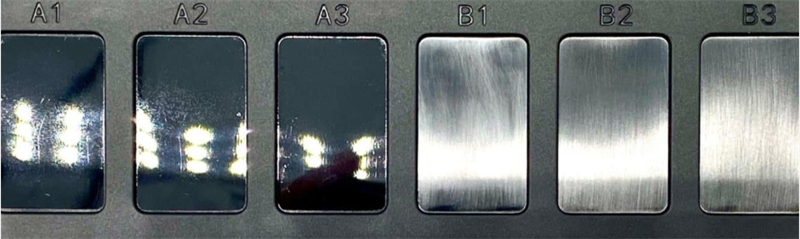

(SPI-AB Jekiseni-kuumba pamusoro pekupedzisira)

Aya magiredhi "A" anopedzisa akatsetseka, anopenya, uye anodhura zvakanyanya.Aya magiredhi angada akaomeswa zviumbwa zvesimbi, izvo zvinoputirwa uchishandisa akasiyana mamakisi edhaimondi buff.Nekuda kweiyo yakatsetseka-zviyo yekuputira paste uye isina kurongeka inotenderera inotenderera yekupukuta nzira, haizove nemavara akajeka uye kuparadzira mwenje mwenje, ichipa kupenya kwakanyanya.Aya anonziwo "Diamond finish" kana "buff finish" kana "A finish"

| Finish | SPI Standard | Finish Method | Surface roughness(Ra Value) |

| Yakanyanya Yakakwirira Inopenya Pedzisa | A1 | 6000 Grit diamond buff | 0.012 kusvika 0.025 |

| High Glossy Pedzisa | A2 | 3000 Grit diamond buff | 0.025 kusvika 0.05 |

| Normal Glossy Finish | A3 | 1200 Grit diamond buff | 0.05 kusvika o.1 |

SPI gloss mamakisi akakodzera kune zvigadzirwa zvine yakatsetseka pamusoro pekupedzisira nekuda kwezvizoro uye zvinoshanda zvikonzero.Semuyenzaniso, A2 ndiyo yakajairika madhaimani kupera kushandiswa muindasitiri, zvichikonzera zvikamu zvakanaka zvinooneka zvinofadza nekuburitswa kwakanaka.Pamusoro pezvo, giredhi "A" rinopera rinoshandiswa pazvikamu zvemaziso zvakaita semalenzi, magirazi uye mavhairasi.

Semi-gloss kupera - Grade B

(mufananidzo 2.SPI-AB Jekiseni-kuumba pamusoro pekupedzisira)

Aya semi-gloss anopedzisa akanakira kubvisa machining, kuumba, uye makiyi ekushandisa ane mutengo unonzwisisika wekushandisa.Aya mapeji epamusoro anogadzirwa pachishandiswa mamakisi akasiyana emasandpaper akaiswa ane mutsara kufamba, achipa mutsara pateni sezvakaratidzwa mumufananidzo 2.

| Finish | SPI Standard | Finish Method | Surface roughness(Ra Value) |

| Fine Semi Glossy Finish | B1 | 600 Grit Pepa | 0.05 kusvika 0.1 |

| Medium Semi Glossy Finish | B2 | 400 Grit Pepa | 0.1 kusvika 0.15 |

| Normal emi Glossy Pedzisa | B3 | 320 Grit Pepa | 0.28 kusvika o.32 |

SPI(B 1-3) semi-gloss surface inopera yaizopa chitarisiko chakanaka uye kubvisa mold tool marks.Izvi zvinowanzo shandiswa muzvikamu zvisiri zvekushongedza kana zvinoonekwa zvakakosha chikamu chechigadzirwa.

Mate finish - Grade C

Aya ndiwo akanyanya hupfumi uye akakurumbira pamusoro pekupedzisira, akakwenenzverwa achishandisa dombo rakanaka.Dzimwe nguva inonzi kupera kwebwe, inopa kusunungurwa kwakanaka uye inobatsira kuvanza machining marks.Giredhi C zvakare inhanho yekutanga yemagiredhi A uye B pamusoro pekupera.

| Finish | SPI Standard | Finish Method | Surface roughness(Ra Value) |

| Medium Matte Finish | C1 | 600 Grit Stone | 0.35 kusvika 0.4 |

| Medium Matte Finish | C2 | 400 Grit Pepa | 0.45 kusvika 0.55 |

| Normal Matte Finish | C3 | 320 Grit Pepa | 0.63 kusvika 0.70 |

Textured finish - Giredhi D

Iyo inopa chikamu chinonzwisisika chinotaridzika chitarisiko uye chinoshandiswa zvakanyanya muzvikamu zveindasitiri uye zvinhu zvevatengi.Izvi zvakakodzerwa nezvikamu zvisina chaiwo zvinoonekwa zvinodiwa.

| Finish | SPI Standard | Finish Method | Surface roughness(Ra Value) |

| Satin Texture Finish | D1 | 600 ibwe isati yaoma kuputika girazi bead#11 | 0.8 kusvika 1.0 |

| Dry Texture Finish | D2 | 400 dombo risati raoma girazi rinoputika #240 oxide | 1.0 kusvika 2.8 |

| Rough Texture Finish | D3 | 320 ibwe isati yaoma kuputika #24 oxide | 3.2 kusvika 18.0 |

Hapana akambotaura kuti kugadzira nekugadzira zvikamu zvakaumbwa zvaive nyore.Chinangwa chedu ndechekukupfuudza iwe nekukurumidza uye nemhando dzemhando.

VDI Jekiseni kuumba pamusoro pekupedzisira

VDI 3400 Surface Finish (inowanzozivikanwa seVDI pamusoro pekupedzisa) inoreva kuumbwa kwechimiro chakaiswa naVerein Deutscher Ingenieure (VDI), iyo Sosaiti yeGerman Injiniya.Iyo VDI 3400 pamusoro pekupedzisira inonyanya kugadziriswa neMagetsi Discharge Machining (EDM) kana mold machining.Inogonawo kuitwa nenzira yechinyakare yekutumira mameseji (senge muSPI).Kunyangwe iwo zviyero zvakatemerwa nzanga yeGerman Injiniya inowanzoshandiswa pakati pevagadziri vezvishandiso kwese, kusanganisira North America, Europe, uye Asia.

VDI kukosha kwakavakirwa pamusoro peiyo roughness.Kubva pamufananidzo, tinoona maumbirwo akasiyana-siyana epamusoro pekupedzisira ane maitiro akasiyana-siyana ekuoma kwepamusoro.

| VDI kukosha | Tsanangudzo | Applications | Kushata kwepamusoro (Ra µm) |

| 12 | 600 Dombo | Low polish parts | 0.40 |

| 15 | 400 Dombo | Low polish parts | 0.56 |

| 18 | Dry Blast Glass Bead | Satin kupera | 0.80 |

| 21 | Dry Blast # 240 Oxide | Dull finish | 1.12 |

| 24 | Dry Blast # 240 Oxide | Dull finish | 1.60 |

| 27 | Dry Blast # 240 Oxide | Dull finish | 2.24 |

| 30 | Dry Blast # 24 Oxide | Dull finish | 3.15 |

| 33 | Dry Blast # 24 Oxide | Dull finish | 4.50 |

| 36 | Dry Blast # 24 Oxide | Dull finish | 6.30 |

| 39 | Dry Blast # 24 Oxide | Dull finish | 9.00 |

| 42 | Dry Blast # 24 Oxide | Dull finish | 12.50 |

| 45 | Dry Blast # 24 Oxide | Dull finish | 18.00 |

Mhedziso

Kubva mumapoka maviri ejekiseni rekuumbwa kwepasi rinopera, SPI giredhi A uye B inoonekwa seyakatsetseka ine yakaderera zvakanyanya roughness uye inodhura.Nepo, kubva pahukukutu hwekutarisa, VDI 12, iyo yepamusoro mhando VDI, yakaenzana SPI C giredhi.

Hapana akambotaura kuti kugadzira nekugadzira zvikamu zvakaumbwa zvaive nyore.Chinangwa chedu ndechekukupfuudza iwe nekukurumidza uye nemhando dzemhando.

Nzira yekusarudza jekiseni rakakodzera rekuumba pamusoro pekupedzisira?

Sarudza jekiseni rekuumba rinopedzisa nekufunga chikamu chebasa, zvinhu zvinoshandiswa, uye zvinoonekwa zvinodiwa.Mazhinji eakajairwa epurasitiki jekiseni akaumbwa zvinhu anogona kuve akasiyana epamusoro pekupedzisira.

Sarudzo yekupedzisa kwepamusoro inofanirwa kugadzikwa mukutanga embodiment dhizaini dhizaini yechigadzirwa nekuti iyo yepamusoro inoraira kusarudzwa kwezvinhu uye dhizaini angle, ichipesvedzera mutengo wekushandisa.Semuyenzaniso, kosi kana mameseji kupedzisa kunoda yakakosha dhizaini kona kuitira kuti chikamu chibviswe kubva mukuumbwa.

Saka ndezvipi zvinhu zvekutanga zvekufunga nezvazvo pakusarudza iyo yekumusoro kupera kwemajekiseni ekuumba mapurasitiki?

Gloss kupera Giredhi A (Kwakabva:XR USA Mutengi)

Mutengo wekushandisa

Kupedzwa kwepamusoro uye zvinhu zvinopesvedzera zvakanyanya dhizaini yedhizaini uye mutengo, saka funga uye ongorora mashandiro acho maererano nepamusoro pekutanga pane embodiment dhizaini.Kana iyo yepamusoro pekupedzisira yakakosha pakushanda kwayo, funga nezve kupera kwepamusoro pamatanho ekufungidzira ekugadzirwa kwechigadzirwa.

Zvikamu zvakawanda zvemajekiseni ekuumba maitiro akave otomatiki, asi polishing inosiyana.Ndiwo chete akareruka ezvimiro anogona kukwenenzverwa otomatiki.MaPolisher ave nemidziyo uye zvekushandisa zviri nani zvekushanda nazvo, asi maitiro acho anoramba achinyanya kushanda.

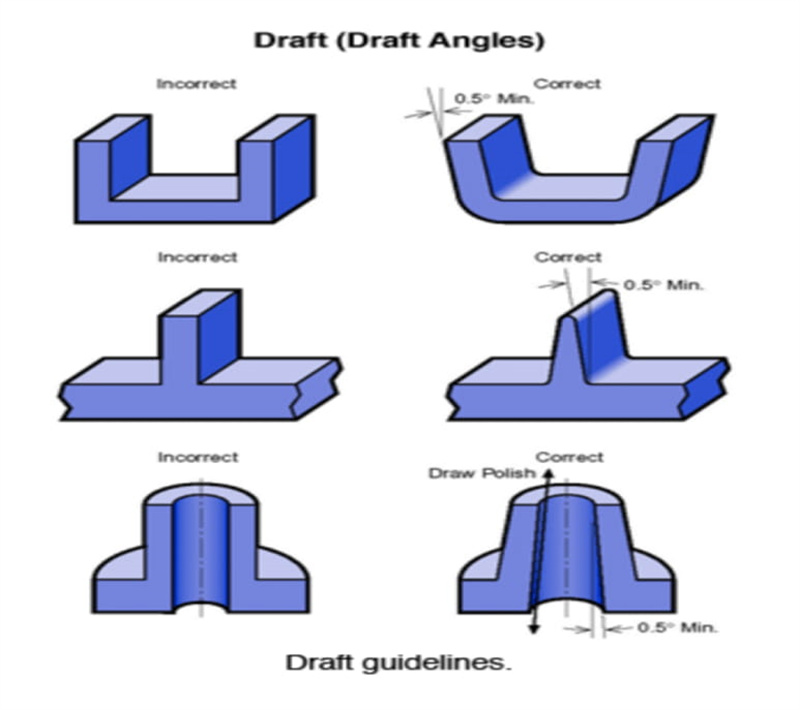

Draft angle

Zvikamu Zvizhinji Zvinoda Draft Angle ye1½ kusvika 2 Degrees

Uyu ndiwo mutemo wechigunwe unoshanda kune zvikamu zvakaumbwa zvine hudzamu hunosvika masendimita maviri.Nehukuru uhu, dhizaini inosvika 1½ madhigirii inokwana kuti nyore kuburitswa kwezvikamu kubva mukuumbwa.Izvi zvinobatsira kudzivirira kukuvadzwa kune zvikamu kana iyo thermoplastic zvinhu inoderera.

Mold tool zvinhu

Iyo mold tool inokanganisa zvakanyanya kutsetseka kwepamusoro kwejekiseni rekugadzira.Mold inogona kugadzirwa kubva kune akasiyana simbi, kunyangwe simbi nealuminium ndizvo zvinonyanya kufarirwa.Mhedzisiro yesimbi idzi mbiri pazvikamu zvepurasitiki zvakaumbwa zvakasiyana zvakanyanya.

Kazhinji, simbi yakaomeswa yesimbi inogona kugadzira yakatsetseka epurasitiki kupera kana ichienzaniswa nealuminium alloy maturusi.Saka funga zviumbwa zvesimbi kana zvimedu zvine basa rekunakisa rinoda mwero wakaderera wekushata kwepamusoro.

Molding material

Yakasiyana-siyana majekiseni ekuumba mapurasitiki anowanikwa kuti avhare marudzi ese ezvikamu uye mabasa.Nekudaro, haazi ese mapurasitiki anogona kuwana yakafanana jekiseni rekuumba pamusoro pekupedzisira.Mamwe mapolymers anokodzera zvirinani kupedzisa kutsetseka, nepo mamwe akakodzera zvirinani kuita roughening kumusoro kune yakawedzera kugadzirwa.

Kemikari uye hunhu hwemuviri hunosiyana pakati pemajekiseni ekuumba zvinhu.Kunyungudika tembiricha, semuenzaniso, chinhu chakakosha mukukwanisa kwechinhu kupa humwe hunhu hwepamusoro.Zviwedzerwa zvinewo zvazvinoita pamhedzisiro yechigadzirwa chakapedzwa.Nekuda kweizvozvo, zvakakosha kuti uongorore zvakasiyana siyana usati wasarudza pamusoro pemhando yepamusoro.

Uyezve, zvinhu zvinowedzera senge filler uye pigment zvinogona kukanganisa kupera kwechinhu chakaumbwa.Matafura ari muchikamu chinotevera anoratidza kushanda kweakati wandei majekiseni ekuumba emhando dzakasiyana dzeSPI yekupedzisa.

Kukodzera kwezvinhu zveGiredhi SPI-A pamusoro pekupedzisa

| Material | A-1 | A-2 | A-3 |

| ABS | Avhareji | Avhareji | Kugona |

| Polypropylene (PP) | Hazvikurudzirwi | Avhareji | Avhareji |

| Polystyrene (PS) | Avhareji | Avhareji | Kugona |

| HDPE | Hazvikurudzirwi | Avhareji | Avhareji |

| Nylon | Avhareji | Avhareji | Kugona |

| Polycarbonate (PC) | Avhareji | Kugona | Excellent |

| Polyurethane (TPU) | Hazvikurudzirwi | Hazvikurudzirwi | Hazvikurudzirwi |

| Acrylic | Excellent | Excellent | Excellent |

Kukodzera kwezvinhu zveGiredhi SPI-B pamusoro pekupedzisa

| Material | B-1 | B-2 | B-3 |

| ABS | Kugona | Kugona | Excellent |

| Polypropylene (PP) | Kugona | Kugona | Excellent |

| Polystyrene (PS) | Excellent | Excellent | Excellent |

| HDPE | Kugona | Kugona | Excellent |

| Nylon | Kugona | Excellent | Excellent |

| Polycarbonate (PC) | Kugona | Kugona | Avhareji |

| Polyurethane (TPU) | Hazvikurudzirwi | Avhareji | Avhareji |

| Acrylic | Kugona | Kugona | Kugona |

Kukodzera kwezvinhu zveGiredhi SPI-C pamusoro pekupedzisa

| Material | C-1 | C-2 | C-3 |

| ABS | Excellent | Excellent | Excellent |

| Polypropylene (PP) | Excellent | Excellent | Excellent |

| Polystyrene (PS) | Excellent | Excellent | Excellent |

| HDPE | Excellent | Excellent | Excellent |

| Nylon | Excellent | Excellent | Excellent |

| Polycarbonate (PC) | Avhareji | Hazvikurudzirwi | Hazvikurudzirwi |

| Polyurethane (TPU) | Kugona | Kugona | Kugona |

| Acrylic | Kugona | Kugona | Kugona |

Kukodzera kwezvinhu zveGiredhi SPI-D pamusoro pekupedzisira

| Material | D-1 | D-2 | D-3 |

| ABS | Excellent | Excellent | Kugona |

| Polypropylene (PP) | Excellent | Excellent | Excellent |

| Polystyrene (PS) | Excellent | Excellent | Kugona |

| HDPE | Excellent | Excellent | Excellent |

| Nylon | Excellent | Excellent | Kugona |

| Polycarbonate (PC) | Excellent | Hazvikurudzirwi | Hazvikurudzirwi |

| Polyurethane (TPU) | Excellent | Excellent | Kugona |

| Acrylic | Avhareji | Avhareji | Avhareji |

Molding parameters

Jekiseni kumhanya uye tembiricha inokanganisa kupera kwepasi nekuda kwezvikonzero zvishoma.Paunosanganisa kukurumidza jekiseni kumhanya nepamusoro kunyunguduka kana mold tembiricha, mhedzisiro inowedzerwa kupenya kana kutsetseka kwechikamu chepamusoro.Muchokwadi, kukurumidza jekiseni kumhanya kunovandudza kupenya kwese uye kutsetseka.Pamusoro pezvo, kukurumidza kuzadza kwegomba rekuumbwa kunogona kuburitsa mitsara isingaonekwe weld uye yakasimba aesthetic mhando yechikamu chako.

Kusarudza kupera kwechikamu chepamusoro chinhu chakakosha mukukura kwechigadzirwa uye chinofanira kufungwa panguva yekugadzira dhizaini kuti uwane izvo zvaunoda.Wakambofunga nezvekupedzisira kushandiswa kwejekiseni rako rakaumbwa chikamu?

Rega Xiamen Ruicheng akubatsire kusarudza pamusoro pekupedzisa kunovandudza aesthetics uye kushanda kwechikamu chako.

Nguva yekutumira: May-22-2023