Ruicheng inyanzvi mukugadzira jekiseni rekuumba maindasitiri zvinhu.Yedu inoshanda uye yakaringana majekiseni ekuumba maitiro anotibvumira kune zvigadzirwa zvemhando yepamusoro uye iwe unogona accounting kune purojekiti kugadzirisa chigadzirwa chepurasitiki ndechako.Isu tine kugona kuzadzisa ese epurasitiki maindasitiri echikamu zvinodiwa maererano nezvinhu, saizi, maumbirwo, kushivirira, nezvimwe.

Yakajairika maindasitiri epurasitiki chigadzirwa

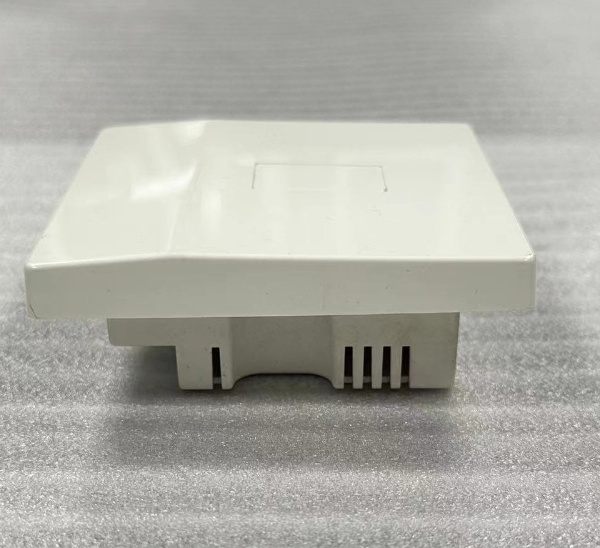

Ichi chigadzirwa ndeye Standard Smart WIFI Bata Mwenje Shandura dzimba dzinogadzirwa nezvikamu zvepurasitiki zvemaindasitiri uye zvinoenderana neyakajairwa yeAmerica.

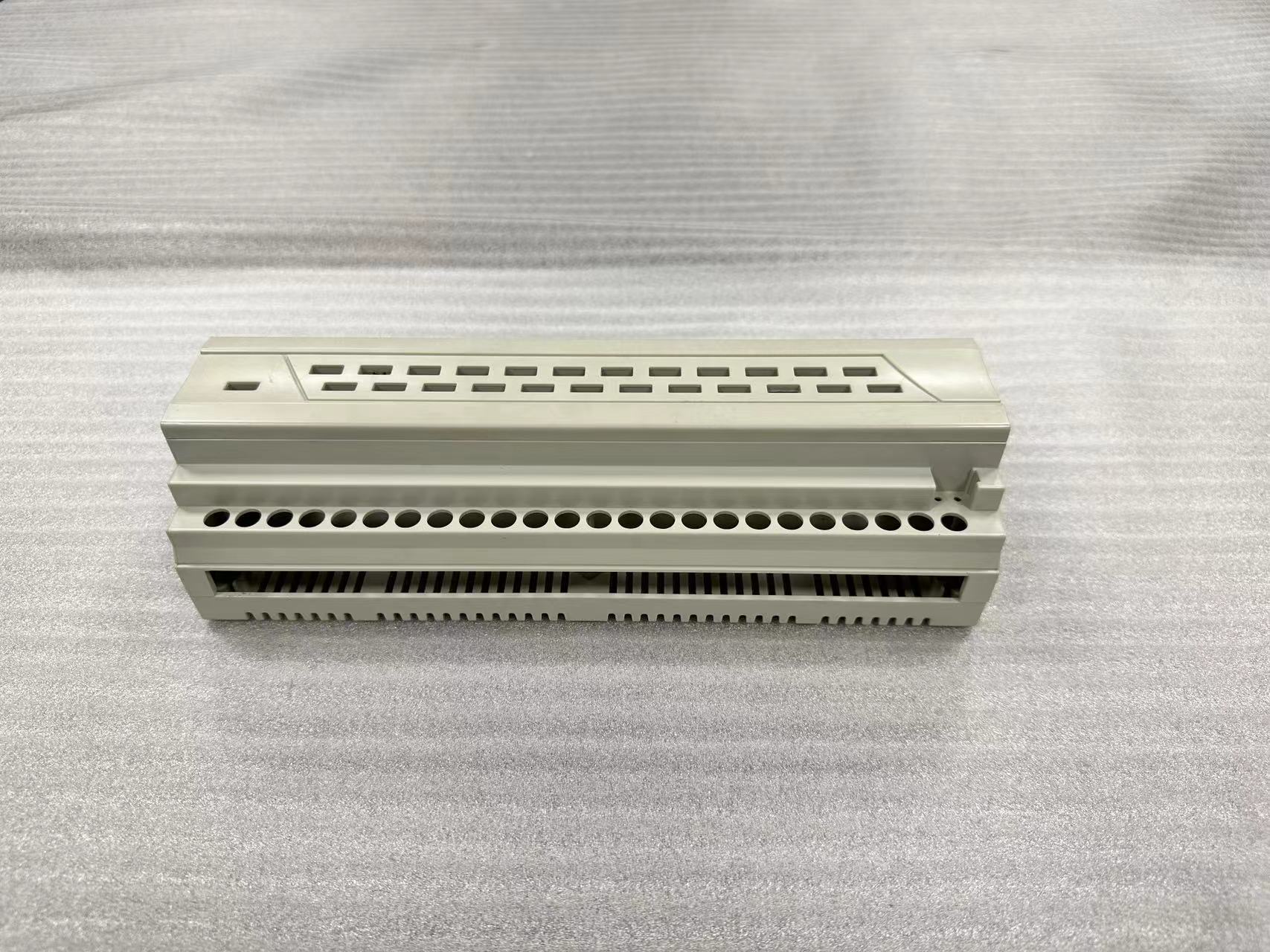

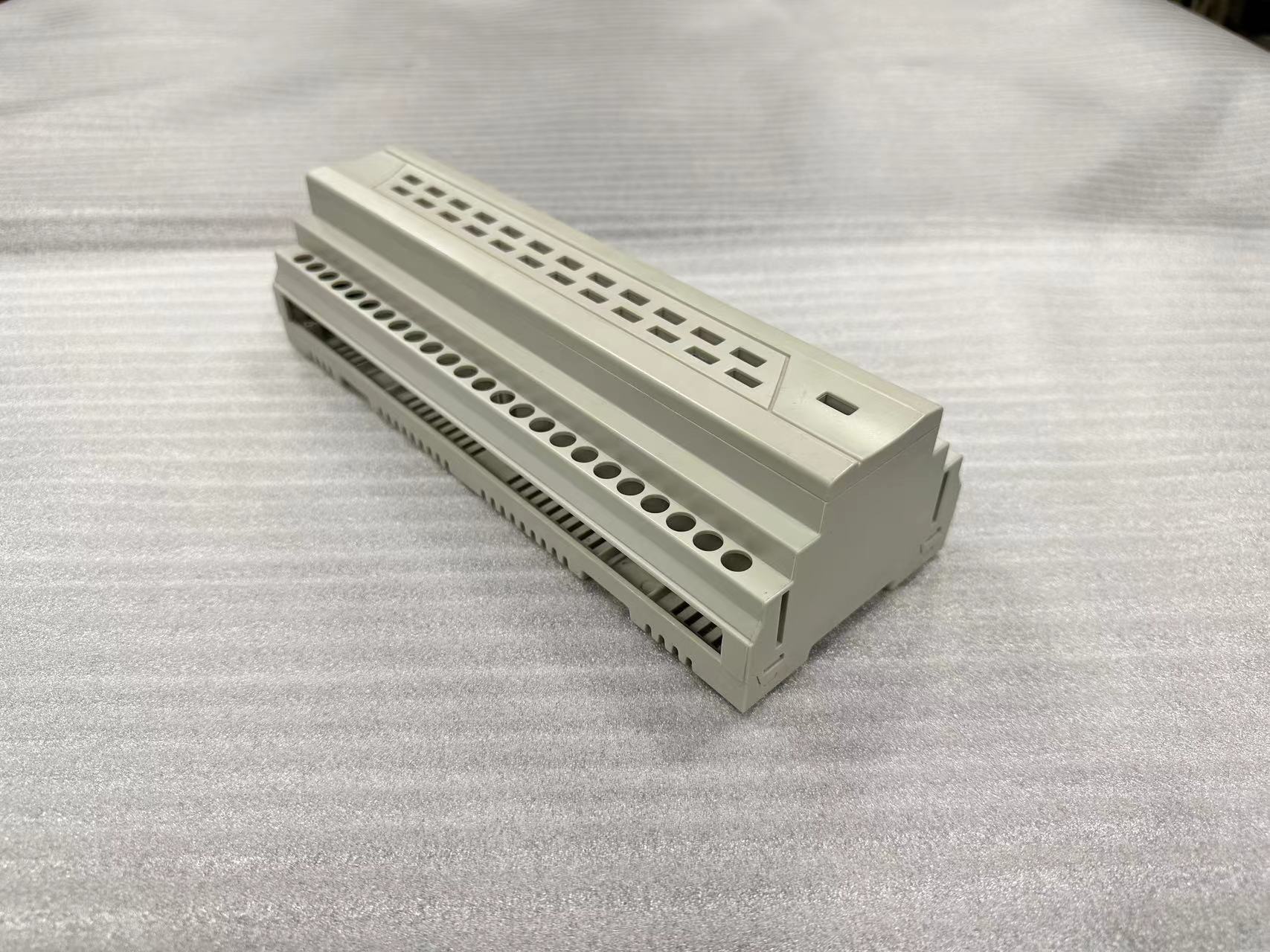

Yakagadzirirwa Industrial Plastic Parts ine yakanaka isina mvura uye UV kuramba, izvo zvinoita kuti chigadzirwa ichi chishande zvakanaka munzvimbo yekunze.

Yakagadzirwa ne100% mhandara yepurasitiki zvinhu, isu tichaita yakasimba yehutongi hwehutongi panguva yekuumbwa kwejekiseni, uye kuitisa mhando uye kuongororwa kwegungano panguva imwe chete.Pakupedzisira, tichazviendesa kwauri mune yedu yakanaka yekuchengetedza package.

4.Plastic Overmold Inopinza Chibatanidza

Iyi yakagadziridzwa indasitiri yekuchaja yekubatanidza yakakodzera kune magetsi mudziyo unotsigira.Inogona kupa vimbiso yekuisa yemidziyo yako uye kuita kuti zvive nyore kwauri kushandisa.

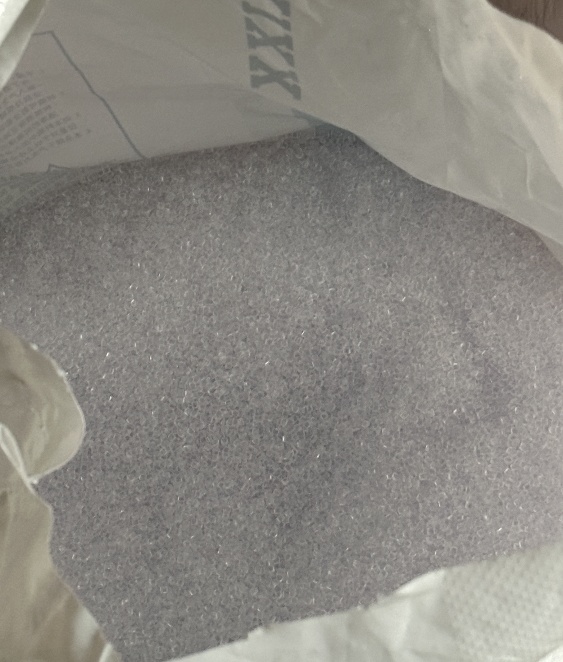

Ndezvipi zvinhu zvaunogona kusarudza kugadzira maindasitiri epurasitiki chigadzirwa

ABS:

Acrylonitrile Butadiene Styrene (ABS) inonzi thermoplastic iyo inogadzirwa nekushandisa emulsion.Neyo Yakasimba, inoshanduka, yakaderera mold shrinkage (tight tolerances), kupikisa kwemakemikari, electroplating simba, zvakasikwa opaque, yakaderera / yepakati mari.

PA66:

PA66 ndeimwe yenaironi, ine hunhu hwakafanana nenaironi, inowanzo shanda mumabatiro, marevhisi, madiki edzimba, zip tie & magiya, mabhushi.

PC

PC yakaoma kwazvo nekuramba tembiricha uye kugadzikana kwedimensional, inogona kuitwa pachena asi nemutengo wakakwira.

PP

PP iri muhuremu nekudzivirirwa nekupisa, kukwirira kwemakemikari kuramba, kuramba kukwenya uye chitarisiko chewakisi chakaoma uye chakasimba mumutengo wakaderera.

TPU:

TPU ndeye elastic zvinhu zvine kumira zvakanaka kumafuta, girisi, uye abrasion.

Yakajairika maitiro eindasitiri epurasitiki chigadzirwa

Jekiseni molding inzira yekugadzira inoshandiswa kugadzirwa kwakawanda kwezvikamu zvepurasitiki zvakafanana.Inzira yejekiseni repurasitiki apo purasitiki yakanyungudutswa inopinzwa muforoma kuti ibudise chikamu muchimiro chegomba rekuumba, ichigadzira chimiro chechimiro chezvikamu zvepurasitiki zvakamisikidzwa.

Iko kushandiswa kwejekiseni rekuumba tekinoroji kugadzira zvigadzirwa zvemaindasitiri zvinogona kuita kugadzirwa kwakawanda, izvo zvinogona kuderedza mutengo wemabhizinesi, kupfupisa nguva dzekutumira mushandisi, uye kugadzira zvigadzirwa zvemhando yepamusoro.

Pamusoro pezvo, jekiseni dzakaumbwa zvikamu zvakagadzirwa nejekiseni zvinoratidza kugadzikana kwakanyanya uye zvirashwa zvadzo zvinogona kudzokororwa, zvichibatsira kubvisa tsvina.

Overmolding

Overmolding inzira yekugadzira iyo imwe (polymer) zvinhu zvinoumbwa kana kukandwa pane chimwe chinhu chingave chakaumbwa, simbi, kana polymer muzvisikwa.Mhedzisiro yacho chinhu chimwe chete, chakabatanidzwa chemidziyo miviri iyo inowanzova nemabasa akasiyana muchikamu chakapetwa.Kushandiswa kwemaitiro aya pazvikamu zvemaindasitiri epurasitiki kwakajairika.Silicone inowanzoputirwa pazvikamu zvepurasitiki kudzivirira kutsvedza, senge mabhurashi emazino, sando, madhiraini emagetsi, nezvimwe. Kana ikashandiswa kune imba yezvigadzirwa zvemagetsi, inowanzova yekudzivirira.

Kuwedzeredza uye jekiseni kuumba maitiro akafanana anoshandiswa kugadzira (kazhinji) zvikamu zvepurasitiki.Vanosiyana chete pakuti iyo overmolding process ndeyechipiri oparesheni.

Kutanga tisati tatanga, tinoda kuti utumire iyo 3d kudhirowa uye zvinodiwa kwatiri.Nyanzvi inoongorora chirongwa ichi, ongorora zvimiro zvayo uye zviyero zvekukurukura uye kufunga nezvekugadzira mold (senge gedhi rejekiseni, mapini, dhizaini angle etc.)

Chechipiri, mushandi wedu achaverengera hunhu hwechigadzirwa chako kuseta muchina wejekiseni.Kana chishandiso ichivhara, zvichireva kutanga kwejekiseni molding cycle.

Mapolymer granules anozoomeswa uye oiswa muhopi, obva adyiswa mudhiramu, maanobva apiswa panguva imwe chete, anosanganiswa uye oendeswa kune mold neinosiyana pitch screw.Iyo geometry yescrew uye mbiya yakagadziridzwa kubatsira kuvaka kudzvanywa kune iyo chaiyo mazinga uye kunyungudutsa zvinhu.

Mushure mekuzadza mold cavity nepurasitiki, inofanira kubvumirwa kutonhora.Mvura yakatenderedzwa kazhinji senzira huru yekuita tembiricha isingaperi sezvo zvinhu zvinoomesa.

Kana zvinhu zvatonhora pasi, zvinosimbisa zvakare uye zvinotora chimiro che mold.Pakupedzisira, mold inovhura uye chikamu chakasimba chinosundirwa kunze nemapini ejector.Iyo mold inobva yavhara uye nzira inodzokorora.

Zvigadzirwa zvakapedzwa zvichaiswa nekushandisa bhegi repurasitiki uye kuiswa mumakatoni.Kana iwe uine Special packaging zvinodiwa, tinogonawo kugadzirwa maererano nezvinodiwa nevatengi .Kuitira kuti chigadzirwa chega chega chichaendeswa mumamiriro akanaka.

Kuti udzidze zvakawanda nezve epurasitiki jekiseni craftchimwe chigadzirwa cheindasitiriunogona taura nesutimu yekutengesa kukurukura yako yakasarudzika application.

Nguva yekutumira: Kubvumbi-15-2024