Seimwe yemaitiro echinyakare, stamping inofarirwa zvakanyanya muindasitiri yekugadzira.Kunyanya kune vanogadzira, iyo stamping process inogona kuunza mabhenefiti makuru.Kana iwe uchida kuziva kuti izvi zvinowanikwa sei, ndapota ramba uchiverenga chinyorwa ichi.

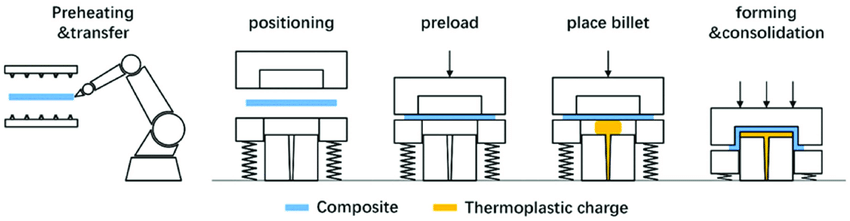

Kutsika-kunonziwo kudzvanya - kunosanganisira kuisa simbi yakatsetseka, mune coil kana fomu isina chinhu, mumuchina wekutsikisa.Muchidhina, mudziyo uye kufa pamusoro zvinoumba simbi muchimiro chaidiwa.Kubaya, kuvhara, kukotama, kuisa mari, embossing, uye flanging ese ndiwo maitiro ekutsikisa anoshandiswa kuumba simbi.

Zvinhu zvisati zvagadzirwa, nyanzvi dzekutsika dzinofanirwa kugadzira chishandiso kuburikidza neCAD/CAM engineering tekinoroji.Aya madhizaini anofanirwa kuve akajeka sezvinobvira kuti ive nechokwadi chekuti punch yega yega uye bend inochengetedza kubvumidzwa kwakaringana uye, nekudaro, yakakwana chikamu chemhando.Chishandiso chimwe chete 3D modhi inogona kuve nemazana ezvikamu, saka maitiro ekugadzira anowanzo kuoma uye anopedza nguva.

Kamwe dhizaini yechishandiso ichinge yasimbiswa, mugadziri anogona kushandisa akasiyana machining, kugaya, waya EDM uye mamwe masevhisi ekugadzira kuti apedze kugadzira kwayo.

1.Kushama

2.Kubaya

3.Kudhirowa

4.Deep Drawing

5.Lancing

6.Bending

7.Kuumba

8.Kucheka

9.Flanging

Zvakanakira tsika stamping maitiro

Kururama

Metal Stamping inomira kunze kwechaunga nekuda kwekushamisa kwayo kudzokororwa nemazvo.Hunhu hwakadzama hwekuita uku hunotibvumira kugadzira zvimiro zvesimbi mumhando dzakaomarara nepo mukana wekukanganisa uri mudiki.

Kubhadhara mari

Metal Stamping inobvumira kudzikisira kwakanyanya kwekugadzirisa nguva uchiwedzera kukurumidza kwekugadzira.Metal stamping inoderedza kushandiswa kwemichina yakawanda, nhamba yevashandi, pamwe nenguva yebasa iyo somugumisiro inoderedza zvakanyanya mari yekugadzira.Iyi nzira yakanakira makambani anoda zviuru zvezvikamu zvemaodha akawanda sezvo ichibvumira kuchengetedza mari kune dzimwe nzira.

Automated process uye kuwedzera kukosha

Paunenge uchifunga nezvebasa repamusoro-soro, unofanirwa kuenzanisa mutengo, mhando, uye vhoriyamu.Metal stamping inoita kuti zvive nyore kwazvo kupedzisa yakakwirira-vhoriyamu basa nekuda kweiyo otomatiki maitiro ayo anosanganisira.Haisi chete maitiro acho akanyanya otomatiki, asi anogona zvakare kubatanidza sekondari mashandiro akadai otomatiki nut kuisa.

Ndeipi simbi stamping process inokodzera purojekiti yako?

Metal stamping inzira yakakurumbira yekugadzira yekugadzira zvikamu zvine kushivirira kwakasimba uchishandisa sheet simbi, sesimbi, mhangura, simbi isina tsvina, uye aluminium.Iwe unogona kutora mukana wesimbi stamping kugadzira zvigadzirwa mumaindasitiri akasiyana akadai se:

1.Motokari

Inoita basa rakakosha muindasitiri yekugadzira mota - kugadzira zvinhu zvakaita semapanera emuviri, mabhuraketi, chassis zvikamu, mamongi einjini, mabhureki, uye zvinhu zvekumisa.Maitiro acho anovimbisa kugadzirwa kwezvakareruka, zvinogara, uye zvimiro zvinonzwika zvikamu zvinosangana nekuchengetedza kwakasimba uye kuita zvinodiwa.

2.Electronics

Muindasitiri yemagetsi, zvigadzirwa zvemagetsi (zvibatanidza, zviteshi, masingi ekupisa, zvidziviriro zvekudzivirira, uye mabhuraketi) zvinoshandiswa zvakanyanya.Metal stamping yakaita kuti zvikwanisike kugadzirwa chaiko kwezvikamu zvakaomarara zvinodiwa pamagungano emagetsi uku uchipa humbowo hwemagetsi uye kusimba.

Electronic Housing Stamping Chikamu

3.Kumba midziyo

Maitiro aya anoshandiswawo zvakanyanya mukugadzira midziyo yemumba yakaita sefiriji, muchina wekuwachisa, oveni, uye masisitimu eHVAC.Iyo inogadzira zvinhu zvakaita semapanera, zvakavharirwa, mabhureki, uye zvibatiso, zvichipa zvese zvinoyevedza kukwezva uye kurongeka kwechimiro.

4.Healthcare Industry

Muchikamu chekurapa, zvishandiso zvakaita sezviridzwa zvekuvhiya, orthopedic implants, mabhuraketi, uye zvinobatanidza zvakare zvine zvikamu zvakapfuura nesimbi stamping process kuona kugadzirwa kwechaiyo, sterile, uye biocompatible zvikamu zvakakosha pakushandiswa kwekurapa.

Kana iwe uine chero mapurojekiti ari kuuya ekudhinda uye uchida iyi tekinoroji.

Ndapotataura nesu!

Tinogona kupa tekinoroji yehunyanzvi yekutsikisa kuti ikubatsire.

Nguva yekutumira: Mar-19-2024