Stamping inzira yekugadzira inoshandiswa kuumba kana kuumba simbi mashizha kana mitsetse nekushandisa simba kuburikidza nefa kana nhevedzano yekufa.Inosanganisira kushandiswa kwekudhinda, iyo inoshandisa kudzvinyirira kune simbi zvinhu, zvichiita kuti iparadze uye itore chimiro chefa.

Ndeapi matanho ekuita stamping?

①Dhizaini uye Injiniya: Iyo maitiro anotanga nedhizaini uye engineering yechikamu chakadhindwa.Izvi zvinosanganisira kugadzira iyo chikamu geometry, kuona izvo zvinongedzo, uye kugadzira iyo inofa uye yekushandisa inodiwa pakuita chitambi.

②Kugadzirira Kwezvinhu: Mashizha esimbi kana mitsetse, inozivikanwa se stock kana ma blanks, inogadzirirwa kudhinda maitiro.Izvi zvinogona kusanganisira kucheka masheya muhukuru hwakakodzera uye chimiro kuti ikwane mafi uye kubvisa chero zvinosvibisa kana kusakwana.

③Die Setup: Iyo inofa, iyo inosanganisira punch uye mhango yekufa, inoiswa mune yekutsikirira.Iwo madhiri akanyatso kurongeka uye akasungirirwa zvakachengetedzeka munzvimbo kuti ave nechokwadi chechokwadi uye chinoenderana chidhindo.

④Kudyisa: Iyo stock material inodyiswa mudhindi redhindi, ingave pamaoko kana otomatiki.Iyo nzira yekudyisa inova nechokwadi chekuti stock yakamira zvakanaka pasi pemafi kune yega yega stamping kutenderera.

⑤Kutsikisa Kushanda: Muchina wekutsikisa unoshandisa huwandu hwakakosha hwesimba kune stock material, zvichiita kuti iparare uye itore chimiro chefa.Danho iri rinowanzo sanganisira kuita chimwe chete kana kupfuura, sekuvhara (kucheka chimiro chaunoda), kukotama (kuumba makona kana macurves), kudhirowa (kutambanudza zvinhu kuti zvipinde muchimiro chakadzika), kana kuumba (kugadzira maitiro chaiwo kana mapatani).

⑥Chikamu Kubviswa: Mushure mekuita kwechitambi kwapera, chikamu chakadhindwa chinobviswa kubva pakufa.Izvi zvinogona kuitwa nemaoko kana nerubatsiro rwe automation, senge robhoti maoko kana maconveyor masisitimu.

⑦Secondary Operations: Zvichienderana nezvinodiwa zvechikamu, mamwe echipiri mashandiro anogona kuitwa.Izvi zvinogona kusanganisira deburring (kubvisa mipendero yakapinza kana maburrs), kupedzisa kwepamusoro (sekupukuta kana kupfekedza), kusangana, kana kuongororwa kwemhando.

⑧Kutariswa Kwemhando: Zvikamu zvakadhindwa zvinoongororwa zvakakwana kuti ive nechokwadi chekuti zvinosangana nemhando yakatarwa.Izvi zvinogona kusanganisira kuyerwa kwedimensional, kuongorora kwekuona, kuyedzwa kwezvinhu, kana mamwe maitiro ekudzora emhando.

⑨Packaging uye Shipping: Kana zvikamu zvakadhindwa zvapfuura kuongororwa kwemhando, zvinoiswa mukati zvichienderana nezvinodiwa uye zvakagadzirirwa kutumirwa kana kuenderera mberi.

Izvo zvakakosha kuti uzive kuti iwo chaiwo maitiro matanho anogona kusiyana zvichienderana nekuoma kwechikamu, yakasarudzwa nzira yekutsika, uye zvimwe zvinhu zvakanangana nekugadzira kugadzira.

Ona Chii Chinoita Kuti Stamping Ikurumbire

Mutengo-unoshanda: Stamping inopa mabhenefiti emutengo nekuda kwekuita kwayo kwakanyanya kugadzira.Iyo nzira inobvumira kukurumidza uye otomatiki kugadzirwa kwehuwandu hukuru hwezvikamu, kuderedza mutengo wevashandi uye kuwedzera kwese kudhura-kushanda.

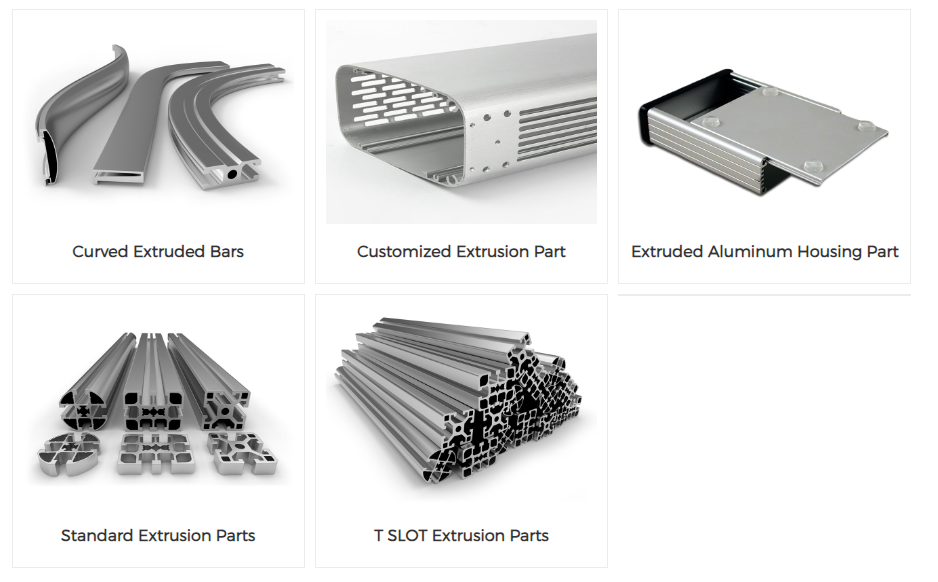

Material Compatibility: Stamping inogona kuiswa kune akasiyana zvinhu, zvinosanganisira simbi (sesimbi, aruminiyamu, uye mhangura) uye mamwe mapurasitiki.Uku kuchinjika kunobvumira vagadziri kuti vasarudze akanyatsokodzera zvinhu kune avo chaiwo maapplication, vachifunga zvinhu zvakaita sesimba, kusimba, uye conductivity.

Yakanyanya Kurongeka: Matampu maitiro anogona kuwana akakwira mazinga ekurongeka kwedimensional uye kudzokorora.Nekushandisa tekinoroji yepamusoro uye tekinoroji yekufa, zvikamu chaizvo uye zvinowirirana zvinogona kugadzirwa, zvichisangana nekushivirira kwakasimba uye zviyero zvemhando.

Kumhanya uye Kubudirira: Kutsikisa mashandiro anowanzo kukurumidza uye anoshanda.Nemaotomatiki ekudya uye matsimba masisitimu, kutsika kunogona kuwana yakakwira mitengo yekugadzira, kuderedza nguva dzekutungamira uye kuwedzera kubereka kwese.

Simba uye Kusimba: Zvikamu zvakadhindwa zvinowanzo ratidza zvakanakisa zvemakanika zvivakwa, zvinosanganisira kusimba, kusimba, uye kusimba.Iyo deformation uye kuomeswa kwebasa kunoitika panguva yekutsikisa kunowedzera kutendeseka kwezvikamu, zvichiita kuti ive yakakodzera kune inoda kunyorera.

Scalability: Stamping inogona kugamuchira zvese zvakaderera uye zvakakwirira-vhoriyamu kugadzirwa zvinodiwa.Yakanyatsokodzera kugadzirwa kwehuwandu nekuda kweiyo yakakwirira-kumhanya, otomatiki maitiro.Panguva imwecheteyo, inogona zvakare kuchinjirwa kune madiki ekugadzira anomhanya kana prototyping, ichipa kuchinjika mukusangana kwakasiyana kwekugadzira zvinodiwa.

Kubatanidzwa neMamwe Maitirwo: Stamping inogona kubatanidzwa nyore nyore nemamwe maitiro ekugadzira akadai sewelding, kusangana, uye kupera kwepasi.Izvi zvinobvumira kukwenenzverwa kwekugadzira workflows uye kugadzirwa kwemagungano akaoma kana zvigadzirwa zvakapedzwa.

Pakusarudza iyo stamping process zvinoenderana nemamiriro chaiwo, zvinhu zvakati wandei zvinofanirwa kutariswa:

Material: Ziva rudzi rwesimbi kana alloy ichadhindwa.Simbi dzakasiyana dzine hunhu hwakasiyana uye zvimiro, senge simba, ductility, uye ukobvu.Funga nezvezvinodiwa chaizvo zvechikamu kana chigadzirwa uye sarudza stamping process inokodzera zvinhu zvakasarudzwa.

Kuoma kweChikamu: Ongorora kuoma kwechikamu kana dhizaini yechigadzirwa.Ona kana iine zvimiro zvakaomarara, mabhende, kana zvinhu zvakaita sekunamisa kana kuboora.Yakasiyana-siyana yekudhirowa, senge kuvharika, kukotama, kana kudhirowa kwakadzika, inokodzera mhando dzakasiyana dzechikamu geometries.

Kugadzira Vhoriyamu: Funga nezve inodiwa vhoriyamu yekugadzira.Matampu maitiro anogona kuchinjirwa kune ese ari pasi-vhoriyamu uye yakakwira-vhoriyamu kugadzirwa.Pakugadzirwa kwepamusoro-vhoriyamu, kufambira mberi kwekufa kutsika kana kutamisa chitambi kungave kwakakodzera, nepo kune yakaderera-vhoriyamu kana prototype kugadzirwa, imwe-nhanho kana komboni kufa stamping inogona kushandiswa.

Kushivirira uye Kwakajeka: Ongorora inodiwa dimensional kurongeka uye kushivirira kwechikamu chakadhindwa.Mamwe maitiro ekutsika, senge kuvharika kwakanaka kana kudhinda chaiko, anogona kuwana kushivirira kwakaomarara uye kurongeka kwepamusoro zvichienzaniswa nemaitiro akajairwa ekutsika.Funga nezveyero yekurongeka inodiwa kune chaiyo chikamu kana chigadzirwa.

Surface Pedzisa: Ongorora inodiwa pamusoro pekupedzisira kwechikamu chakadhindwa.Mamwe maitiro ekutsika anogona kusiya mamakisi kana kuda mamwe matanho ekupedzisa kuti uwane yaunoda pamusoro pemhando.Funga kana mabasa echipiri akadai sekubvisa kana kupukuta achidiwa.

Tooling uye Equipment: Ongorora kuwanikwa uye mutengo wekushandisa nemidziyo inodiwa pakuita chitambi.Maitirwo akasiyana ekudhinda angangoda kufa chaiko, zvibhakera, kana midziyo yekutsikirira.Funga nezve nguva yekutungamira uye mutengo wekushandisa, pamwe nekugona kwekutora kana kugadzirisa midziyo inodiwa.

Mutengo uye Kubudirira: Ongorora iyo yakazara mutengo-kubudirira uye kugona kweiyo stamping maitiro.Funga zvinhu zvakaita semitengo yezvinhu, mari yekushandisa, nguva yekutenderera kwekugadzira, kushandiswa kwesimba, uye zvinodiwa nevashandi.Enzanisa zvakanakira uye zvipimo zveakasiyana masitampu maitiro kuti uone iyo inodhura-inoshanda sarudzo kune chaiyo kugadzirwa zvinodiwa.

Nekunyatso tarisa zvinhu izvi uye kubvunzana nenyanzvi mundima yekutsikisa, senge xiamenruicheng, unogona kuita sarudzo ine ruzivo uye sarudza yakanyatso dhinda maitiro emamiriro ako chaiwo.

Nguva yekutumira: Feb-21-2024