Vacuum casting, inozivikanwawo sesilicone molding kana polyurethane casting, inzira yekugadzira inoshandiswa kugadzira akawanda makopi eprototype kana chikamu.Inowanzo shandiswa mumunda wekukurumidza prototyping uye yakaderera-vhoriyamu kugadzirwa.

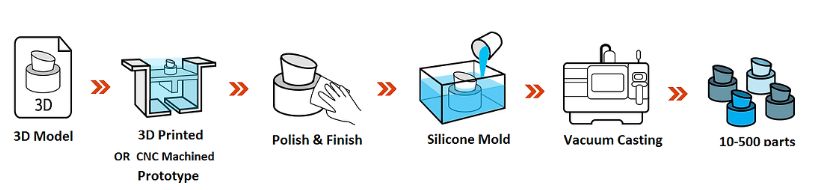

Ndeapi matanho ekugadzirisa vacuum casting?

①Master Model Kusikwa: Inyanzvi modhi inotanga kugadzirwa uchishandisa 3D kudhinda, CNC machining, kana imwe nzira yakakodzera.Iyo master modhi inomiririra chimiro chinodiwa, chimiro, uye ruzivo rwechikamu chekupedzisira kana chigadzirwa.

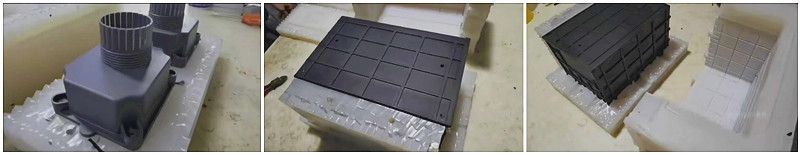

②Kugadzirira Mold: Iyo silicone mold inogadzirwa kubva kune master modhi.Iyo tenzi modhi inoiswa mumudziyo, uye mvura silicone inodururwa pamusoro payo, ichivhara modhi zvachose.Iyo silicone inozobvumidzwa kurapa, ichigadzira inochinjika uye yakasimba mold.

③Mold Assembly: Kana iyo silicone mold yapora, inochekwa kuita hafu, ichigadzira mhango.Iwo mahafu anobva aunganidzwa zvakare achishandisa maumbirwo ekugadzirisa kuti ave nechokwadi chekurongeka panguva yekukanda.

④Material Casting: Iyo inodiwa yekukanda zvinhu, kazhinji polyurethane resin, inogadzirwa.Iyo mold inotaridzirwa kune imwe tembiricha uye inoiswa mukamuri yevacuum.Iyo vacuum kamuri yakavharwa, uye vacuum inoshandiswa kubvisa chero mweya wakavharirwa kana magasi kubva mukuumbwa.

⑤Kudurura uye Kurapa: Iyo yakagadzirwa yakakandwa zvinhu inodururwa mugomba rekuumbwa kuburikidza nekaburi kadiki kana sprue.Iyo vacuum pressure inobatsira kukwevera zvinhu muforoma, kuve nechokwadi chekuzadza kwakaringana uye kuderedza mabhuru emhepo.Iyo mold inobva yasiiwa isina kukanganiswa kuti zvinhu zvirape uye zviome.

⑥Kubvisa Mold uye Kupedzwa: Mushure mekunge zvinhu zvekukanda zvanyatsopora, mold inovhurwa, uye chikamu chemufananidzo chinobviswa.Chero chinhu chakawandisa kana kupenya kunochekwa uye kubviswa.Chikamu chinogona kuita mamwe matanho ekugadzirisa mushure, sejecha, kupenda, kana kupedzisa kwepamusoro, kuti uwane aesthetics inodiwa uye kushanda.

Ona Chii chinoita kuti vacuum casting Ikurumbire

Mutengo-Kubudirira: Inobvisa kudiwa kwemidziyo inodhura, senge jekiseni molds, iyo inogona kuderedza zvakanyanya mutengo wepamberi.

Speed uye Nguva Yokutungamirira:Magetsi ekugadzira mapfupi sezvo pasina kudikanwa kwekushandisa kwakaoma kana kuseta kwakakura.

Speed uye Nguva Yokutungamirira: Vacuum casting inopa kukurumidza kutendeuka nguva kana ichienzaniswa nemaitiro echinyakare ekugadzira.

Surface Finish uye Aesthetics: Vacuum casting inogona kuendesa yepamusoro-yemhando yepamusoro kupera, kudzokorora chitarisiko uye magadzirirwo echinodiwa chekupedzisira chigadzirwa.Inogadzira zvikamu zvine nzvimbo dzakatsetseka, kuderedza kudiwa kweakawanda post-processing kana kupedza.

Nzira yekusarudza sei vacuum casting process zvinoenderana nemamiriro chaiwo?

Kusarudza iyo chaiyo vacuum yekukanda maitiro kune yako chaiyo mamiriro kunosanganisira kufunga akati wandei.Heano mamwe maitiro akakosha ekubatsira kutungamira sarudzo yako:

Zvinodikanwa zvechishandiso: Tanga nekuona izvo zvemukati zvivakwa zvinodiwa kune yako prototype kana chigadzirwa.Funga zvinhu zvakaita sekuoma, kuchinjika, kujeka, uye kudzivirira kupisa.Vacuum casting inotsigira zvakasiyana-siyana zvekukanda zvinhu, zvinosanganisira polyurethane (yakaomarara uye inochinjika), silicone rabha, uye akajeka resin.Sarudza vacuum casting process iyo inogona kugadzirisa zvaunoda zvinhu zvingasarudzwa.

Huwandu uye Kugadzira Vhoriyamu: Sarudza huwandu hwezvikamu zvaunoda kugadzira.Vacuum casting yakanyatsokodzera kune yakaderera kusvika pakati mavhoriyamu ekugadzira.Kana iwe uchida batch diki yemaprototypes kana mashoma ekugadzira anomhanya, vacuum casting inogona kuve inodhura mhinduro kana ichienzaniswa nedzimwe nzira dzekugadzira senge jekiseni rekugadzira.

Detail Replication uye Surface Pedzisa: Ongorora nhanho yekudzokorodza kwezve uye kupera kwepamusoro kunodiwa kune zvikamu zvako.Vacuum casting inozivikanwa nekugona kwayo kunyatso kuburitsa zvakadzama zvakadzama, maumbirwo, uye undercuts.Kana dhizaini yako ichisanganisira yakanaka maficha kana yakaoma geometries, vacuum casting inogona kuunza yakakwirira-kutendeseka replicas.Funga nezvesarudzo dzepamusoro dzekupedzisira dziripo neakasiyana vacuum casting maitiro kuti ive nechokwadi chekuzadzisa zvaunoda.

Zvipingamupinyi Nguva: Ongorora nguva yeprojekti yako uye zvinodiwa pakuchinja.Vacuum casting inowanzopa kukurumidza kutungamirira nguva zvichienzaniswa nemaitiro echinyakare ekugadzira.Funga nezvenguva inodiwa yekugadzira mold, kukanda, uye mushure mekugadzirisa.Vamwe vanopa masevhisi vanogona kupa masevhisi anomhanyisa kana akawanda ekukanda michina, ayo anogona kuderedza nguva yekutungamirira.Kana nguva yakaoma, sarudza vacuum casting process inogona kusangana neyako yaunoda nguva.

Kufunga Kwemari: Ongorora bhajeti rako uye zvinokutadzisa mutengo.Vacuum casting inogona kuve inodhura-inoshanda mhinduro yeakaderera-vhoriyamu kugadzirwa uye prototyping.Enzanisa mutengo une chekuita nekugadzira mold, mashandisirwo emidziyo, uye post-kugadzirisa kune vakasiyana vacuum casting sevhisi vanopa.Iva nechokwadi chekutarisa kukosha kwese uye hutano hunounzwa nesarudzo yega yega.

Zvimwe Zvinodiwa: Chengetedza chero zvimwe zvinodiwa zvakanangana neprojekiti yako.Semuenzaniso, kana iwe uchida overmolding kana kuisa molding kugona, shuwa kuti yakasarudzwa vacuum casting process inotsigira zvinhu zvakadaro.Funga chero zvitupa kana zviyero izvo zvikamu zvaungada kutevedzera, senge ISO kana FDA zvinodiwa.

Nekufunga zvinhu izvi, unogona kuita sarudzo ine ruzivo pamusoro pevacuum casting process inonyatsokodzera mamiriro ako chaiwo.Pamusoro pezvo, iwe unogona kubvunza nekambani yedu yevacuum casting masevhisi kuti uwane imwe nzwisiso uye nhungamiro.

Nguva yekutumira: Zvita-04-2023