Warpage deformation inoreva kukanganiswa kwechimiro chejekiseni chakaumbwa chigadzirwa uye warpage, kutsauka kubva kune chimiro chechokwadi chinodiwa chechikamu, ndicho chimwe chezvikanganiso kugadzirisa mujekiseni mold dhizaini nekugadzira.

Chii chinokonzera nyaya uye nzira yekuvandudzaizvozvo?

Mamiriro ekuumbwa, iyo thermophysical zvimiro zvepurasitiki zvinhu uye mamiriro uye maparamendi ekugadzirisa maitiro ese ane madhigirii akasiyana ekupesvedzera pane warpage uye deformation yechigadzirwa.

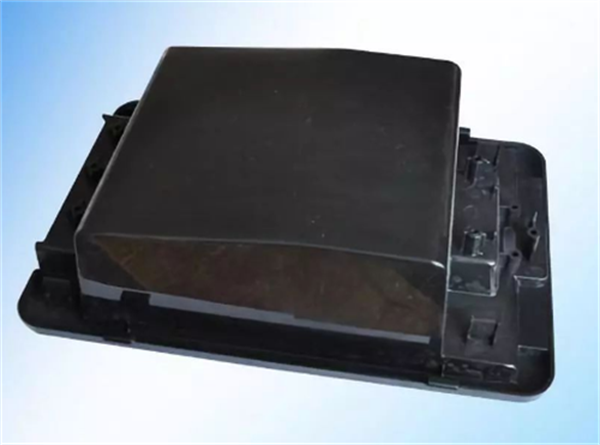

1. Mold defects

Dhizaini ye mold inosarudza iyo warpage maitiro echikamu, uye zvakanyanya kuoma kudzvanya tsika iyi nekushandura mamiriro ekuumba, saka mhinduro yekupedzisira inofanira kutanga kubva pakugadzira mold nekuvandudza.

(1) Kuvandudza mold kuitira kuti kukora uye kunaka kwechikamu kuve kwakafanana.

(2) dhizaini yekutonhodza sisitimu yekugadzira mold cavity tembiricha yunifomu muzvikamu zvese, kukora kwakakodzera kweiyo yakanyanya kuoma kuita chikamu che manifold, iyo huru yekuyerera chiteshi, kupfupisa kuyerera kureba, nepazvinobvira kubvisa iyo Musiyano wemhango density, kudzvanywa musiyano, tembiricha musiyano.

(3) Nzvimbo yekushandura uye makona ehukobvu hwechikamu inofanira kunge yakatsetseka zvakakwana uye iine yakanaka mold kuburitswa, sekuwedzera muganho wekuburitsa, kuvandudza kukwenenzverwa kwenzvimbo yekuumbwa, kuderedza ukobvu hwechando kana uchizadza mold. , kuderedza kushushikana kwemukati uye kuchengetedza kuenzana kweiyo ejector system.

(4) Kuita kuti pave nemhepo yakanaka.

(5) Wedzera madziro emadziro echikamu kana kuwedzera iyo warp kuramba kutungamira, nekusimbisa iyo yekusimbisa kusimbisa iyo warp kuramba kwechikamu.

2. Kudzora kusina kunaka kwekugadzirisa uye kuumba mamiriro

Mukuita jekiseni rekuumba, purasitiki yakanyungudutswa mune jekiseni mold yekuzadza nhanho nekuda kwekurongeka kwemapolymer mamorekuru padivi pekuyerera kuitira kuti ipurasitiki iri munzira yekuyerera ye shrinkage rate pane yakatwasuka nzira ye shrinkage rate, uye jekiseni rakaumbwa. zvikamu zvewarpage deformation (kureva anisotropy).Kazhinji, yunifomu shrinkage inongokonzera shanduko muhuwandu hwechikamu chepurasitiki, chete shrinkage isina kuenzana ndiyo inokonzeresa warpage deformation.

Kudzvanywa kwejekiseni, chiyero uye mamwe ma paramita emushini wejekiseni, kuzadza uye kutonhora nhanho yekushisa, kudzvanywa, kumhanya kwevatatu pamwe chete, maitiro ejekiseni, mutsauko wekushisa pakati pematunhu akasiyana anokonzerwa nekupisa kwekupisa, deformation kana kupisa. kusaenzana shrinkage inokonzeresa nguva yekukotama, inogona kuita kuti zvikamu zvepurasitiki warpage deformation

(1) Deredza kudzvanywa kwejekiseni uye kupfupisa nguva yekubata kuti uone tembiricha yakakwana yekunyungudika kudzivirira warpage nekuda kwekuwedzera kushushikana kwemukati.

(2) Deredza tembiricha yekuumbwa uye kuwedzera nguva yekutonhora kudzivirira kupisa kwechikamu panguva yekudhirowa uye ejection deformation.

(3) Deredza screw kumhanya uye kumashure kumanikidza kuderedza density uchichengetedza hushoma kubhadharisa kudzikamisa kushushikana kwemukati.

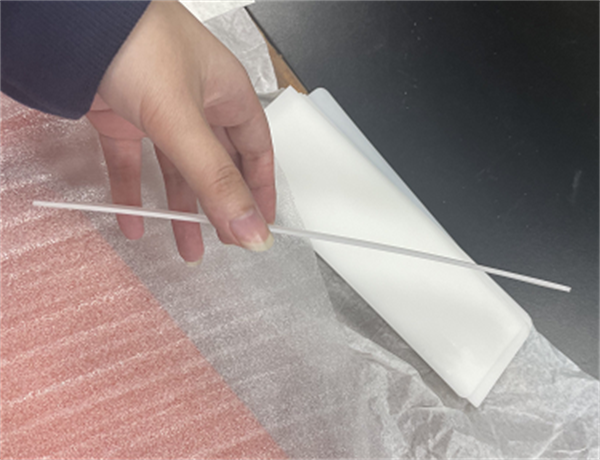

(4) Kana zvichidikanwa, kuumbwa kwakapfava kana kudhonzwa mushure mekudhirowa kunogona kuitwa kune zvikamu zvinowanzoita warpage uye deformation.

Pakuumbwa kwejekiseni, kuchave nematambudziko mazhinji, Xiamen Ruicheng ane anopfuura makore makumi maviri ruzivo mune ino ndima, iyo inogona kukupa iwe tsigiro yehunyanzvi uye rubatsiro.Unoda kuziva zvakawanda here?Bata nesu izvozvi!

Nguva yekutumira: Feb-03-2023