1.Kurapa Kurapa: Imwe yenzira dzakajairika dzekurapa pamusoro pehardware ndeyekupfekedza kurapwa, senge galvanizing, nickel plating, uye chroming.Coatings inopa chidziviriro chekudzivirira pamusoro pesimbi yesimbi, inosimudzira kusimba kwayo uye inovandudza chitarisiko.Coatings inogonawo kuwedzera kuoma uye kupfeka kusagadzikana kwesimbi.

2.Painting Treatment: Painting inzira yakajairika yekurapa pamusoro pe hardware, apo chivharo chekudzivirira chinoshandiswa nekupfapfaidza pendi kana kuvhara pamusoro pesimbi.Kupenda kunogona kupa mavara akasiyana-siyana nemhedzisiro, kuvandudza chitarisiko uye kupa mabasa senge corrosion resistance uye scratch resistance.

3.Kupisa Kurapa: Kurapa kwekupisa kunosanganisira kushandura chimiro uye maitiro ezvigadzirwa zvehardware nekupisa uye kutonga kutonhora.Nzira dzakajairika dzekurapa kupisa dzinosanganisira annealing, quenching, uye tempering.Kurapa kwekupisa kunogona kuvandudza kuoma, simba, uye corrosion kuramba kwehardware kusangana nezvinodiwa zvekushandisa.

4.Kuchenesa Kurapa: Kupukuta ndiyo nzira yekuita kuti simbi yepamusoro igare yakatsetseka uye inopenya kuburikidza nemichina kana makemikari nzira.Kuchenesa kunogona kubvisa kukanganisa, maokisi, uye zvinosvibisa kubva kune hardware pamusoro, kuvandudza chitarisiko uye tactile kunaka.

5.Brushing:Kubhurasha inzira yakajairika yekupedzisa simbi inoshandiswa zvakanyanya kushandura chitarisiko uye magadzirirwo emasimbi.Inoshandiswa kune zvakasiyana-siyana zvesimbi zvakadai sesimbi isina tsvina, aluminium uye mhangura.Kubhurasha kunopa kutaridzika nekunzwa kwakasiyana kune simbi kuburikidza nemuchina kana kemikari kurapa pamusoro pesimbi kuti ibudise mutsara mutsara kana makwara.

6.Anodizing:Anodizing inzira yakajairika yekurapa pamusoro inoshandiswa kune aluminium uye alloys ayo.Inosanganisira kuumbwa kweiyo oxide layer pamusoro pealuminium kuburikidza ne electrochemical process, inosimudzira kusakara kwayo, kuoma, uye kusapfeka.

7.Laser engraving:Laser engraving inzira inoshandisa tekinoroji yelaser kuisa pamusoro pechinhu.Inonyungudutsa kana kuita oxidize zvinhu zviri pamusoro pechinhu kuburikidza nekutarisa uye neradiation yeyakakwira-simba laser beam, zvichikonzera pateni, chinyorwa kana mufananidzo mukudzika kana kudzika.

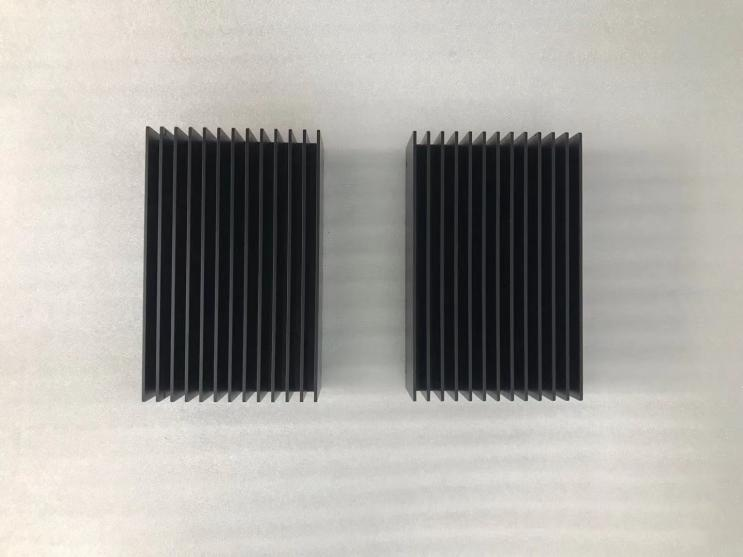

8.Blackening:Blackening kurapwa kwepamusoro kunowanzoshandiswa kune zvigadzirwa zvesimbi, kunyanya zvinhu zvesimbi.Inoshandiswa kusviba ruvara uye kuwedzera kuomarara kwepasi nekugadzira dema oxide layer pane simbi.

9.Dacromet (Dacro) :Dacromet (Dacro) izita rekutengeserana kwesimbi yekupedzisa uye anti-corrosion coating.Iyo yepamberi anticorrosive coating tekinoroji iyo inonyanya kushandiswa kuchengetedza simbi nesimbi zvigadzirwa kubva mukuora uye oxidation.

Dacromet coatings kazhinji inosanganisira zvinotevera zvikamu:

Chromate-isina Primer: Iyi ndiyo primer layer yeDacromet coating, iyo isina inokuvadza chromium compounds.Basa rekutanga reiyo primer kupa yakanakisa adhesion uye corrosion kuramba uchipa hwaro hweyunifomu yejasi repamusoro.

Corrosion-resistant Intermediate Coating: Ichi chikamu chakakosha cheDacromet coating.Iyo yepakati pemukati ine zvakasiyana-siyana zve corrosion inhibitors uye corrosion-resistant pigments iyo inobudirira kudzivirira kuparara uye oxidation yepasi pesimbi.

Organic Coating: Iyi ndiyo yekunze dhizaini yeDacromet coating uye inowanzo organic resin coating.Iyo haingopi chete ruvara uye yekushongedza mhedzisiro, asiwo inowedzera kusimba uye scratch kushorwa kwejasi.

10.Sandblasting:Sandblasting, inozivikanwawo sekutsvaira kwejecha, kukwenenzvera jecha, kana pneumatic sandblasting, inzira yakajairika yekugadzira pamusoro inoshandiswa kuchenesa, kukorobha, kana kunatsiridza magadzirirwo echinhu.

Pakusarudza mushonga wepamusoro wesimbi, zvinhu zvakati wandei zvinofanirwa kutariswa:

Chinangwa uye zvinodiwa: Chekutanga, tarisa chako chaicho chinangwa uye zvinodiwa zvesimbi yepasi kurapwa.Urikuvavarira kuchengetedza simbi kubva mukuora uye oxidation, kuvandudza kunaka kwemavara, kuwedzera kushongedza mhedzisiro, kana kuwedzera kunamira kwekunamatira?Nzira dzekurapa dzakasiyana dzinopa mhedzisiro dzakasiyana zvichienderana nezvinangwa zvakasiyana uye zvinodiwa.

Rudzi rwemhando: Funga nezvemhando uye maitiro esimbi.Simbi dzakasiyana, dzakadai sesimbi, aruminiyamu, mhangura, nezvimwewo, dzinogona kuve nekusiyana-siyana kuchinjika kune dzakasiyana nzira dzekurapa pamusoro.Mamwe masimbi anogona kunge ari kuita ngura, nepo mamwe angangoda nzira dzekurapa dzakakosha kuti awedzere kunamira.

Mamiriro ezvakatipoteredza: Funga nezvemamiriro ekunze ayo chigadzirwa chesimbi chichave chichiratidzwa.Kana simbi ichizoonekwa munzvimbo ine mwando, acidic, kana kuita ngura, zvakakosha kusarudza nzira yekurapa pamusoro ine corrosion resistance.Kana simbi ichizoshandiswa kunze, kuramba mamiriro ekunze uye UV kuramba zvakare zvinhu zvekufunga nezvazvo.

Budget uye mutengo: Nzira dzakasiyana dzekurapa dzepamusoro dzinogona kunge dziine mutengo wakasiyana uye matambudziko ekuita.Tarisa bhajeti yako uye zviwanikwa zviripo kuti usarudze nzira inoenderana neyako mari.

Kugoneka uye kushanda: Funga nezvekugoneka uye kushanda kweiyo yakasarudzwa pamusoro pekurapa nzira.Dzimwe nzira dzingada hunyanzvi hwekushandisa uye hunyanzvi, nepo dzimwe dzingave dzakapfava uye dzinowanikwa nyore.Ita shuwa kuti une midziyo inodiwa, hunyanzvi, uye zviwanikwa, kana kuti unogona kuwana rubatsiro rwehunyanzvi.

Tichifunga nezvezvinhu zviri pamusoro apa, unogona kusarudza kubva kune dzakasiyana-siyana dzakakodzera simbi pamusoro pekurapa nzira, kusanganisira sandblasting, electroplating, inopisa-dip galvanizing, anodizing, poda coating, zvichingodaro.Kana iwe usina chokwadi kuti ndeipi nzira inonyanya kukodzera mamiriro ako, unogona kutibvunza.Xiamen Ruicheng akaita marudzi ese esimbi epamusoro kurapwa kune vazhinji vevatinoshanda navo uye akagamuchira ongororo yakanaka.Unyanzvi hwedu uye ruzivo runogona kukupa ruzivo rwakadzama zvichienderana nezvaunoda chaizvo.

Nguva yekutumira: Feb-23-2024