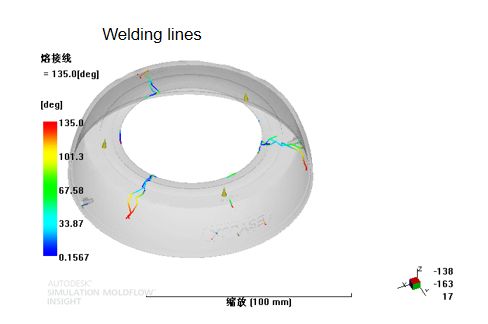

Chii chinonzi welding line

Welding line inonziwo welding mark, flow mark.Mukuita majekiseni ekuumba, kana masuwo akawanda akashandiswa kana maburi aripo mugomba, kana kuisa uye zvigadzirwa zvine shanduko huru muhupamhi hwehupamhi, kuyerera kwepurasitiki kunyunguduka kunoitika mukuumbwa nenzira dzinopfuura maviri.Kana tambo mbiri dzakanyungudika dzichisangana, mutsara we welding uchaumbwa muchikamu.Kunyatsotaura, zvinenge zvese zvigadzirwa zvine mitsetse yewelding, uye zvakaoma kuzvibvisa zvachose, asi kungozvideredza, kana kuita kuti vaende kunzvimbo dzisina basa.

(Welding Line Muenzaniso)

Zvikonzero zvekugadzira welding line

Munguva yekutonhora kwetambo mbiri dzepurasitiki panzvimbo yemutsara we welding, pachava nemhepo yakavharirwa pakati pemapuranga maviri epurasitiki.Mhepo yakavharirwa inovhara mhepo yepolymer mamorekuru uye inoita kuti macheni aparadzane kubva kune mumwe.

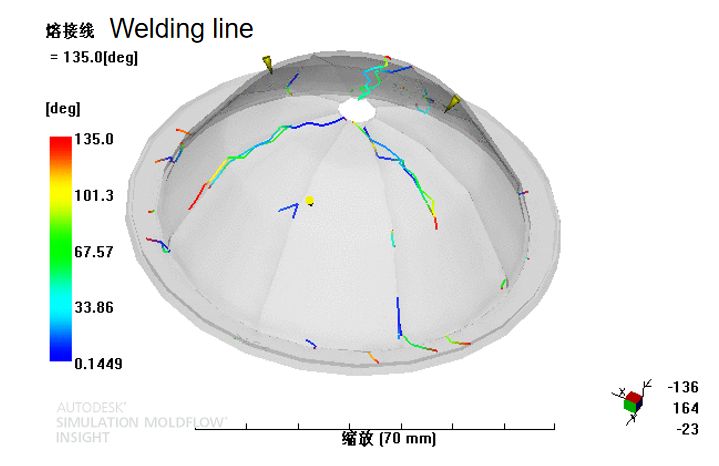

Nzira yekudzikisa sei welding line

Chigadzirwa chekugadzira uye mold design

Kana kutaridzika uye kuita kwechigadzirwa kwakakosha, mutengi nemugadziri we mold vanofanirwa kushanda pamwe chete, kuderedza kukanganiswa kwetambo yewelding zvakanyanya sezvinobvira.Mutengi/mugadziri wechigadzirwa anofanirwa kubatsira mugadziri mukunzwisisa basa rakakodzera rechigadzirwa uye zvakakosha zvekushongedza zvinhu.Mugadziri we mold anofanirwa kufunga nezve chikamu basa uye nzira iyo plastiki inozadza kana kuyerera ichipinda mukati uye kuburikidza nekuumbwa panguva yekugadzira mold chikamu, uchifunga nezve ruzivo rwakakodzera rwunopihwa nemutengi, kuwedzera kubuda kwemhepo munzvimbo yewelding uye kuderedza. mhepo yakavharirwa.Chete kana mutengi nemugadziri we mold vashanda pamwe chete kuti vanzwisise chigadzirwa uye vashande pamwe chete vanogona kuve nechokwadi chekuti nzvimbo ine kashoma welding line kudzvanywa kana kuoneka pane yakanyanya kukosha kutaridzika.

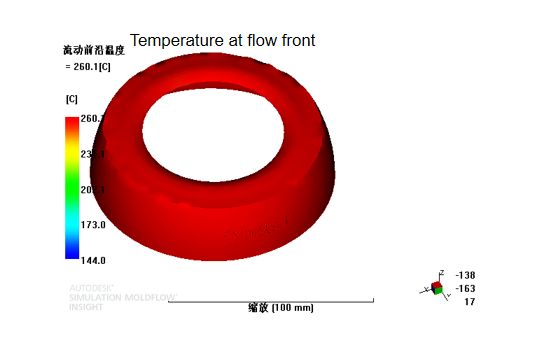

Kusarudzwa kwezvinhu uye kugadzirisa

Zvishandiso zvakasiyana zvine simba rakasiyana-siyana rekushongedza mutsara.Zvimwe zvinyoro zvinyoro zvekubatanidza zvinonzwa kugera uye mitsetse yewelding inogona kuitika kunyangwe tembiricha iri pamberi pekuyerera isina kukanganiswa.Izvi zvingada shanduko yezvinhu kugadzirisa dambudziko remutsara we welding.

Injection molding process kufunga

Thejekiseni kuumbamaitiro anogona zvakare kukanganisa simba uye chinzvimbo cheiyo welding mutsara.Kuchinja kwemaitiro ekupisa uye kudzvanywa kunowanzo kuve nemhedzisiro pamutsetse we welding.

Kana zvichibvira, iva nechokwadi chokuti mutsara we welding unoumbwa panguva yekutanga yekuzadza.Welding line yakaumbwa panguva yekurongedza uye kubata zvikamu zvinowanzonetsa.Kuumbwa kwemitsara yemagetsi panguva yekuzadza kunowanzobatsira kuwedzera chiyero chekuzadza, nokudaro kuderedza nguva yekuzadza uye kuwedzera chiyero chekucheka.Izvi zvinoderedza viscosity yepolymer panguva yekuzadza, zvichikonzera mhepo iri nani yemacheni emamorekuru uye kuzadza kuri nyore.

Dzimwe nguva kuwedzera nguva yekurongedza kana kubata kudzvanywa kuchabatsirawo.Kana chitarisiko chiri nyaya, mwero wakaderera jekiseni unogona kubatsira, asi kazhinji tembiricha yakakwira mold inopa mhedzisiro iri nani.Vacuum venting chishandiso chine simba chinogona kubatsira zvakanyanya mukubatsira nechitarisiko uye nyaya dzesimba.

For morejekiseni kuumbaruzivo, ndapota inzwa wakasunungukataura nesu.

Nguva yekutumira: Zvita-01-2022