Munguva yekuumbwa kwejekiseni, zvakajairika kusangana nekukanganisa kwakasiyana muzvikamu zvakaumbwa, izvo zvinogona kukanganisa kunaka uye kuita kwezvigadzirwa.Ichi chinyorwa chine chinangwa chekuongorora zvimwe zvinowanzoitika muzvikamu zvakaumbwa jekiseni uye kukurukura nzira dzekugadzirisa nyaya idzi.

1.Flow Marks:

Mitsetse inoyerera zvirema zvekuzora zvinoratidzwa nemitsara isina ruvara, mitsetse, kana mapatani anoonekwa pamusoro pechikamu chakaumbwa.Mitsetse iyi inoitika kana purasitiki yakanyungudutswa ichifamba nekumhanya kwakasiyana mukati mejekiseni mold, zvichikonzera mazinga akasiyana ekusimba kweresin.Mitsetse inoyerera inowanzova chiratidzo cheyakaderera jekiseni kumhanya uye/kana kumanikidza.

Pamusoro pezvo, mitsara inoyerera inogona kusimuka kana thermoplastic resin inoyerera munzvimbo dze mold ine akasiyana madziro makubvu.Naizvozvo, kuchengetedza kuenderana kwemadziro ukobvu uye nekuona hurefu hwakakodzera hwema chamfers nemafillet kwakakosha kudzikisa kuitika kwemitsara yekuyerera.Chimwe chiyero chinoshanda ndechekuisa gedhi mune yakaonda-yakakomberedzwa chikamu chechishandiso cavity, iyo inobatsira kuderedza kuumbwa kwemitsara yekuyerera.

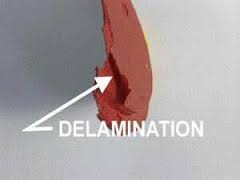

2. Surface Delamination:

Delamination inoreva kupatsanurwa kwematehwe matete pamusoro pechikamu, senge machira anopeuka.Mamiriro aya anoitika nekuda kwekuvapo kwezvisizvo zvisingabatanidzi zvakasvibiswa muzvinyorwa, zvichikonzera kukanganisa kwenzvimbo.Delamination inogonawo kukonzerwa nekunyanya kuvimba ne mold release agents.

Kugadzirisa uye kudzivirira delamination, zvinokurudzirwa kusimudza tembiricha yekuumbwa uye kukwidziridza mold ejection system kuti uderedze kuvimba nevamiriri vanoburitsa mold, sezvo vamiririri ava vachigona kuita kuti delamination.Pamusoro pezvo, kunyatsoomesa-kuomesa kwepurasitiki isati yaumbwa kunogona kubatsira mukudzivirira delamination.

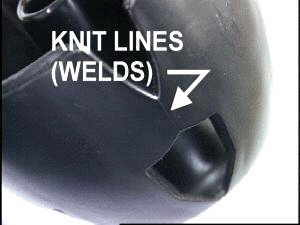

3.Knit mitsetse:

Mitsetse yakarukwa, inozivikanwawo semitsetse yeweld, hurema hunoitika kana kuyerera kuviri kweresin yakanyunguduka kunosangana pavanenge vachifamba nemu mold geometry, kunyanya kutenderedza nzvimbo dzine maburi.Apo plastiki inoyerera uye ichiputira kumativi ose egomba, iyo miviri inoyerera inosangana.Kana tembiricha yeresin yakanyungudutswa isina kunaka, mafambiro maviri anogona kutadza kubatana zvakanaka, zvichikonzera mutsara unooneka we weld.Iyi weld line inoderedza simba rose uye kusimba kwechikamu.

Kuti udzivise kusimba kusati kwasvika, zvinobatsira kuwedzera tembiricha yeresin yakanyungudutswa.Zvakare, kusimudza kumhanya kwejekiseni uye kudzvanywa kunogona kubatsirawo kudzikisira kuitika kwemitsara yakarukwa.Resins ine yakaderera viscosity uye yakaderera kunyungudika mapoinzi haanyanyike kune weld mutsara kuumbwa panguva yekuumbwa kwejekiseni.Pamusoro pezvo, kubvisa zvikamu kubva mukugadzira mold kunogona kubvisa kuumbwa kwemitsara ye weld.

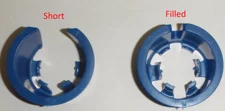

4. Short Shots:

Mapfuti mapfupi anoitika kana resin ikatadza kuzadza zvachose mold, zvichikonzera zvikamu zvisina kukwana uye zvisinga shandiswe.Zvinhu zvakasiyana-siyana zvinogona kukonzera pfuti pfupi mukuumba jekiseni.Zvinowanzokonzeresa zvinosanganisira kuvharirwa kuyerera mukati me mold, izvo zvinogona kuverengerwa kune akamanikana kana kuvharika magedhi, akavharirwa mweya homwe, kana kusakwana kwejekiseni kumanikidza.Material viscosity uye mold tembiricha inogonawo kubatsira kune pfupi shots.

Kuti udzivise kuitika kwepfuti pfupi, zvinobatsira kuwedzera tembiricha yekuumbwa, sezvo izvi zvinogona kuvandudza resin kuyerera.Pamusoro pezvo, kubatanidza kupinza kwekuwedzera mukati mekugadzira mold kunobvumira mweya wakavharirwa kutiza zvinobudirira.Nekugadzirisa zvinhu izvi, mukana wepfuti pfupi mukuumba jekiseni unogona kudzikiswa.

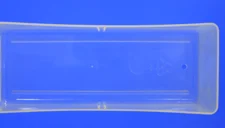

5. Warping:

Warping in jekiseni molding zvinoreva kumonyoroka kusingafungidzirwe kana kukotama muchikamu chinokonzerwa nekuderera kwemukati zvisina kuenzana panguva yekutonhora.Ichi chikanganiso chinowanzobva kune chisina kufanana kana chisingaiti chekutonhora kwe mold, zvichiita kuti chizvarwa chekunetseka kwemukati mukati mezvinhu. kuti zvinhu zvitonhore zvakafanana.Kuchengetedza yunifomu yemadziro emadziro mudhizaini yekuumbwa kwakakosha kune zvikonzero zvakati wandei, zvinosanganisira kufambisa kutsetseka kwepurasitiki kuburikidza negomba rekuumbwa munzira inowirirana.Nekushandisa nzira dzekutonhodza dzakafanira uye kugadzira mold dzine yunifomu yemadziro ukobvu, njodzi yekukanganisa kwewarpage. jekiseni molding inogona kudzikiswa, zvichikonzera zvikamu zvemhando yepamusoro uye zvakadzikama.

6.Jetting:

Jetting kuremara mukuumbwa kwejekiseni kunogona kuitika kana iyo solidification process isina kuenzana.Jetting inoitika apo yekutanga resin jet inopinda mu mold uye inotanga kusimba pamberi pegomba rakazara.Izvi zvinoguma nekuona squiggly kuyerera maitiro pamusoro pechikamu uye kuderedza simba rayo.

Kuti udzivise kukanganiswa kwejetting, zvinokurudzirwa kudzikisa kudzvanywa kwejekiseni, kuve nechokwadi chekuzadza zvishoma nezvishoma kwe mold.Kuwedzera mold uye tembiricha yeresin zvakare inogona kubatsira kudzivirira kusimba kusati kwasvika kwejeti resin.Pamusoro pezvo, kuisa gedhi rejekiseni nenzira inotungamira kuyerera kwezvinhu kuburikidza neakisi ipfupi yeforoma inzira inoshanda yekudzikisa jetting.

Nekuita matanho aya, njodzi yekukanganisa kwejeti mukuumba jekiseni inogona kuderedzwa, zvichitungamira kune yakagadziridzwa mhando yepamusoro uye kuwedzera chikamu simba.

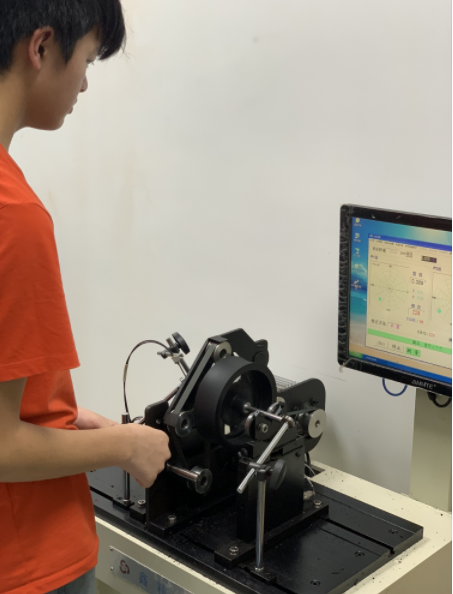

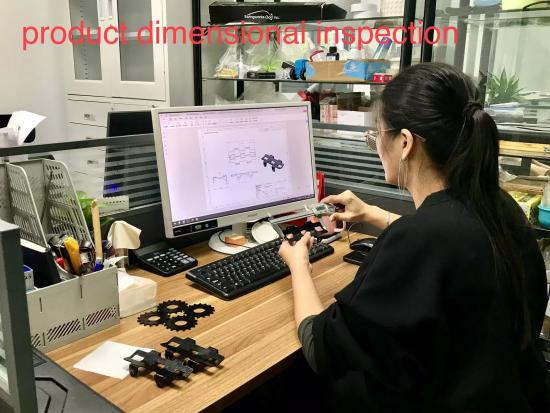

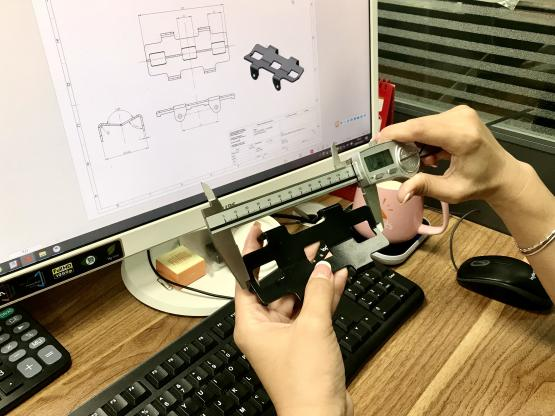

Kambani yedu inotora akati wandei matanho kudzivirira jekiseni kuumba kukanganisa uye kuve nechokwadi chemhando yepamusoro majekiseni akaumbwa zvikamu.Zvinhu zvakakosha zvinosanganisira kusarudza zvigadzirwa zveprimiyamu, dhizaini yakanyatso dhizaini, kunyatso kudzora kwemaitiro paramita, uye yakasimba yemhando yekudzora.Chikwata chedu chinodzidziswa hunyanzvi uye chinoramba chichivandudza uye nekugonesa maitiro ekugadzira.

Kambani yedu inotora akati wandei matanho kudzivirira jekiseni kuumba kukanganisa uye kuve nechokwadi chemhando yepamusoro majekiseni akaumbwa zvikamu.Zvinhu zvakakosha zvinosanganisira kusarudza zvigadzirwa zveprimiyamu, dhizaini yakanyatso dhizaini, kunyatso kudzora kwemaitiro paramita, uye yakasimba yemhando yekudzora.Chikwata chedu chinodzidziswa hunyanzvi uye chinoramba chichivandudza uye nekugonesa maitiro ekugadzira.

Kambani yedu inova nechokwadi chemhando yechigadzirwa nekutevera ISO 9001 quality management system.Isu takagadzira yakakwana yemhando yekutonga system ine yakajairwa maitiro uye maitiro.Tinokurudzira kutora chikamu kwevashandi uye kupa dzidziso nedzidzo.Kuburikidza nematanho aya, tinovimbisa kuti zvigadzirwa zvedu zvakatumirwa zvine mhando yakanaka uye zvinosangana nezvinodiwa nevatengi.

Kusarudzira mudiwa wekugadzira senge xiamenruicheng, ane ruzivo rwakadzama rwezvakajairwa jekiseni kuumba hurema uye kugadziriswa kwavo, kunogona kuita zvakakosha pamhedzisiro yeprojekiti yako.Inogona kunge iri iyo inotaridza pakati pekuwana zvikamu zvemhando yepamusoro, zvinounzwa pahurongwa uye mukati mebhajeti, kana kusangana nematambudziko senge weld mitsara, jetting, flash, sink marks, uye kumwe kukanganisa.Kunze kwehunyanzvi hwedu seyakasimbiswa pane-inodiwa yekugadzira shopu, isu tinopawo dhizaini yekubvunza uye optimization masevhisi.Izvi zvinova nechokwadi chekuti isu tinobatsira timu yega yega mukugadzira zvinoshanda, zvinoyevedza, uye nepamusoro-soro zvikamu nekugona kukuru.Bata nesu nhasi kuti tiongorore yedu yakazara jekiseni molding mhinduro.

Nguva yekutumira: Zvita-15-2023