Extrusion inzira yekugadzira inoshandiswa kugadzira zvinhu zvine muchinjika-chikamu chakamisikidzwa nekusundidzira kana kumanikidza chinhu kuburikidza nefa kana seti yemafi.Izvo zvinhu, kazhinji munzvimbo inopisa kana semi-yakanyungudutswa, inomanikidzwa pasi pekumanikidzwa kukuru kuburikidza nekuvhura kwefa kuti ibudise chimiro chinodiwa nehurefu.Extrusion inowanzoshandiswa kune simbi, mapurasitiki, uye kunyange zvigadzirwa zvekudya.

Ndeapi matanho ekuita extrusion?

Kugadzirira Kwezvinhu: Sarudza yakakodzera mbishi, kazhinji epurasitiki pellets kana simbi mabheti.Zvichienderana nezvinodiwa zvechigadzirwa, iyo mbishi inogona kuda kupiswa kana kufanogadziriswa.

Kudyisa uye Kunyunguduka: Dyisa iyo mbishi kuburikidza nehurongwa hwekudyisa, senge hopper, kupinda muextruder.Mukati me extruder, zvinhu zvinopisa uye zvakanyungudutswa, zvinowanzowanikwa kuburikidza nekupisa screws uye heaters.

Extrusion: Iyo yakanyungudutswa inosundirwa mukati meiyo extruder's screw kana plunger.Iyo screw kana plunger inoshandisa yakanyanya kudzvanywa kuti ifambise zvinhu zvakanyungudutswa kune iyo extrusion die.

Kufa: Iyo yakanyungudutswa inowedzerwa kuburikidza neyakagadzirirwa dhizaini, iyo inosarudza muchinjika-chikamu chimiro chechigadzirwa chekupedzisira.Iyo inofa inowanzogadzirwa nesimbi uye ine yekupinda nekubuda.

Kutonhodza uye Kusimbisa: Izvo zvinhu pakubuda kweiyo extrusion zvinofa nekukurumidza kutonhora, zvichizvibvumira kuomesa uye kuchengetedza yaunoda chimiro.Kutonhora kunogona kuwanikwa kuburikidza nemvura kana kutonhora kwemhepo.

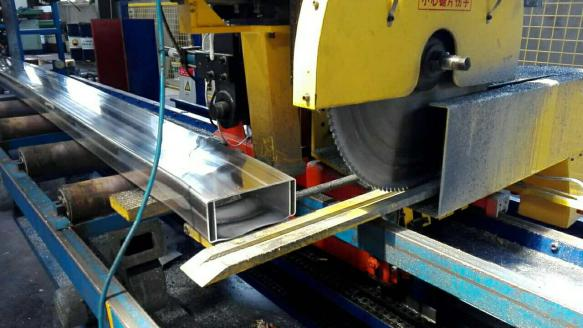

Kucheka uye Kutambanudza: Iyo extruded inoenderera chigadzirwa inochekwa kune yaunoda kureba uchishandisa kucheka michina.Mune zvimwe zviitiko, chigadzirwa chinogona kutambanudza kana kuenderera mberi nekugadzirisa kuti uwane izvo zvinodikanwa zvemuchina.

Post-processing: Zvichienderana nezvinodiwa zvechigadzirwa, mamwe matanho epashure-ekugadzirisa akadai sekurapwa kwepamusoro, kucheka, kupukuta, kana mamwe machining maoparesheni anogona kuitwa.

Ona Chii Chinoita Kuti Extrusion Ikurumbire

Extrusion yakakurumbira nekuda kwezvikonzero zvakati wandei izvo zvinoita kuti iwedzere kutorwa uye mukurumbira:

Mutengo-kushanda: Extrusion inopa zvakanakira mutengo zvichienzaniswa nedzimwe nzira dzekugadzira.Kudyara kwekutanga mumidziyo yeextrusion kunowanzo kuderera, uye maitiro anobvumira kugadzirwa kwakakwira, zvichikonzera kuderera kweyuniti mutengo.Pamusoro pezvo, extrusion inowanzobvisa kudiwa kwekuwedzera machining kana matanho egungano, kuderedza mari yekugadzira yakazara.

Kubudirira uye Kuenderera Kugadzirwa: Extrusion inogonesa kuenderera kugadzirwa, zvichitungamira kune yakakwira kunyatsoshanda uye kubereka.Kana iyo extrusion process yamiswa, inogona kumhanya ichienderera, ichigadzira hurefu hurefu hwezvigadzirwa zvinoenderana.Kuenderera mberi kwekugadzira kunoderedza nguva yekudzikira uye kunowedzera kuburitsa, zvichiita kuti ive yakanakira kugadzirwa kwakakura.

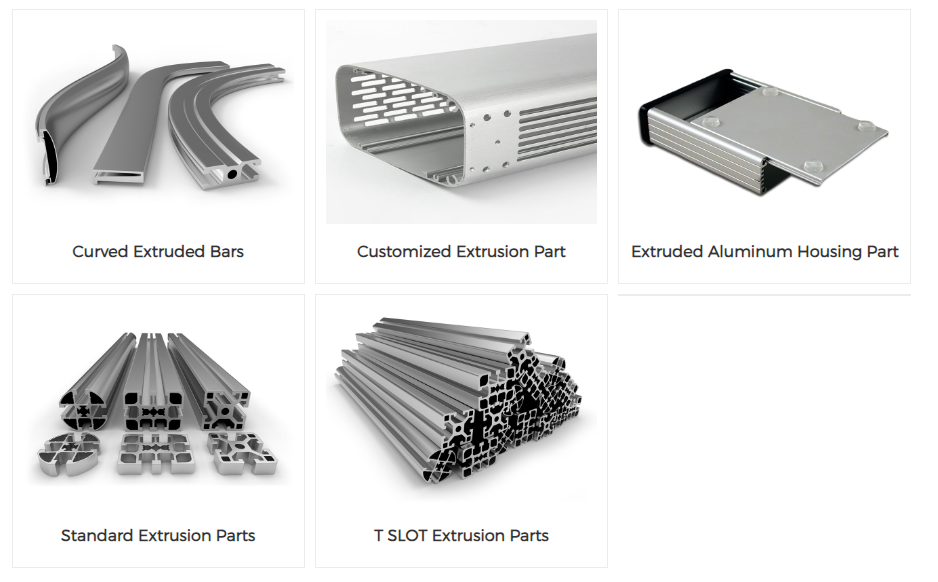

Dhizaini Kuchinjika: Extrusion inopa dhizaini inoshanduka, ichibvumira vanogadzira kugadzira zvigadzirwa zvine chaiwo maprofile, zviyero, uye zvinoshanda.Nekugadzirisa iyo extrusion process paramita uye nekushandisa akasiyana anofa, vagadziri vanogona kuwana akasiyana siyana ekugadzirisa kuti asangane nezvinodiwa chaizvo.

Hunhu Hunoenderana: Extrusion inobvumira kunyatso kudzora pamusoro pezviyero zvechigadzirwa, kushivirira, uye zvinhu zvemukati, zvichikonzera kuenderana uye kwakafanana zvigadzirwa.Kuvimbika uku kwakakosha mumaindasitiri uko kuenderana kwechigadzirwa uye mhando kwakakosha.

Sustainability: Extrusion inogona kubatsira mukusimudzira kuedza.Maitiro acho anogona kushandisa zvakadzokororwa, kuderedza marara uye kusimudzira hupfumi hwakatenderera.Uyezve, extrusion inowanzopedza simba shoma kana ichienzaniswa nedzimwe nzira dzekugadzira, zvichiita kuti ive nehushamwari.

Pakusarudza iyo extrusion process zvinoenderana nemamiriro chaiwo, zvinhu zvakati wandei zvinofanirwa kutariswa:

Material maitiro: Chekutanga, zvinodikanwa kuongorora hunhu hwezvinhu zviri kushandiswa.Zvishandiso zvakasiyana zvine tembiricha yekunyungudika, kuyerera zvivakwa, uye extrusion performance.Kuve nechokwadi chekuti iyo yakasarudzwa extrusion process inogona kugarisa hunhu hwezvinhu kwakakosha kuti uwane zvigadzirwa zvemhando yepamusoro zvakapedzwa.

Zvido zvechigadzirwa: Kunyatsotsanangura zvinodiwa zvechigadzirwa chinhu chakakosha pakusarudza nzira ye extrusion.Funga nezvezvinhu zvakaita sechimiro, saizi, ukobvu hwemadziro, uye kunaka kwepamusoro kwechigadzirwa kuti uone mhando yakakodzera uye ma parameter e extrusion process.

Chiyero chekugadzira: Extrusion maitiro akakodzera kugadzirwa kwakakura, asi akasiyana extrusion michina uye mitsetse ine hunyanzvi hwakasiyana uye hunyanzvi hwekugadzira.Zvichienderana nechiyero chinotarisirwa chekugadzira, sarudza yakakodzera extrusion midziyo uye mutsara kumisikidzwa kuti uve nechokwadi chekusangana nezvinodiwa zvekugona.

Mutengo wekufunga: Kufunga nezve mutengo-kushanda kweiyo extrusion maitiro kwakakosha kune yekugadzira maitiro.Ongorora mari yekudyara, mari yekushandisa, uye mari yekugadzirisa yemidziyo yekuwedzeredza uye woienzanisa neimwe nzira yekusarudza iyo inonyanya kushanda mune hupfumi sarudzo.

Maitiro anochinjika: Mamwe maextrusion maitiro anopa yakakwira maitiro ekuchinja, achibvumira kuchinjika kune akasiyana zvigadzirwa uye zvigadzirwa zvinodiwa.Funga nezvekugadzirisa kwemutsara wekugadzira, kusununguka kwekushanduka kwe mold, uye kushanduka mukugadzirisa extrusion parameters yekukurumidza kugadzirisa uye kuchinja pazvinenge zvichidiwa.

Kudzora kwemhando: Ita shuwa kuti iyo extrusion maitiro anosanganisira akakodzera emhando yekudzora matanho kuti ave nechokwadi chekuenderana kwechigadzirwa uye kutevedzera zvakatemwa.Funga zvinhu zvakaita sekutarisa pamhepo, midziyo yekuongorora, uye masisitimu emhando yepamusoro mukati meiyo extrusion process kuti ive nechokwadi chemhando yechigadzirwa.

Sustainability uye zvakatipoteredza kufunga: Funga zvinhu zvekusimudzira uye kwezvakatipoteredza kukanganisa kweiyo extrusion process.Ongorora pesvedzero yeextrusion process pakushandiswa kwesimba, kubata tsvina, uye kuburitsa kwezvakatipoteredza, uye sarudza maitiro paramita uye zvishandiso zvinoenderana nezvinodiwa kwezvakatipoteredza.

Muchidimbu, kusarudza iyo yakakodzera extrusion maitiro kunoda kutarisisa kwakadzama kwehunhu hwechigadzirwa, zvinodiwa zvechigadzirwa, chiyero chekugadzira, mutengo-unoshanda, kushanduka-shanduka, kutonga kwemhando, uye kusimba.Nekuyera zvinhu izvi zvichienderana nemamiriro chaiwo, iyo yakanyanya kufanirwa extrusion process solution inogona kusarudzwa.

Nguva yekutumira: Feb-20-2024